Hopper Cover Design Project

Client: Pet Food Manufacturer

Partner: MNA Solutions

Service: Engineering Design & Drafting

Status: Concept Developed (Not Implemented)

In the pet food manufacturing industry, where precision and safety underpin every process, an effective maintenance environment is critical. KEVOS® partnered with MNA Solutions to develop a redesigned Hopper Cover for a leading manufacturer, aiming to transform an outdated and hazardous maintenance layout into a safer, more efficient workspace.

Although the concept did not proceed to final approval, the project showcased our commitment to innovative, practical engineering design and reinforced our focus on improving workplace safety through thoughtful solutions.

The Challenge

The existing maintenance layout surrounding the plant’s hoppers—large containers central to material processing—posed significant safety risks. Maintenance staff frequently worked in areas exposed to:

Falling debris

Pinch points

Restricted access

Ergonomically unsafe positioning

These hazards put workers at risk and increased the potential for downtime—an expensive outcome in high-volume manufacturing. The challenge was clear: develop a Hopper Cover solution that eliminated risks without compromising productivity.

Our Approach

We began with a collaborative, on-site assessment alongside MNA Solutions and the manufacturer’s maintenance team. Understanding real operational constraints ensured the design addressed practical needs, not just theoretical scenarios.

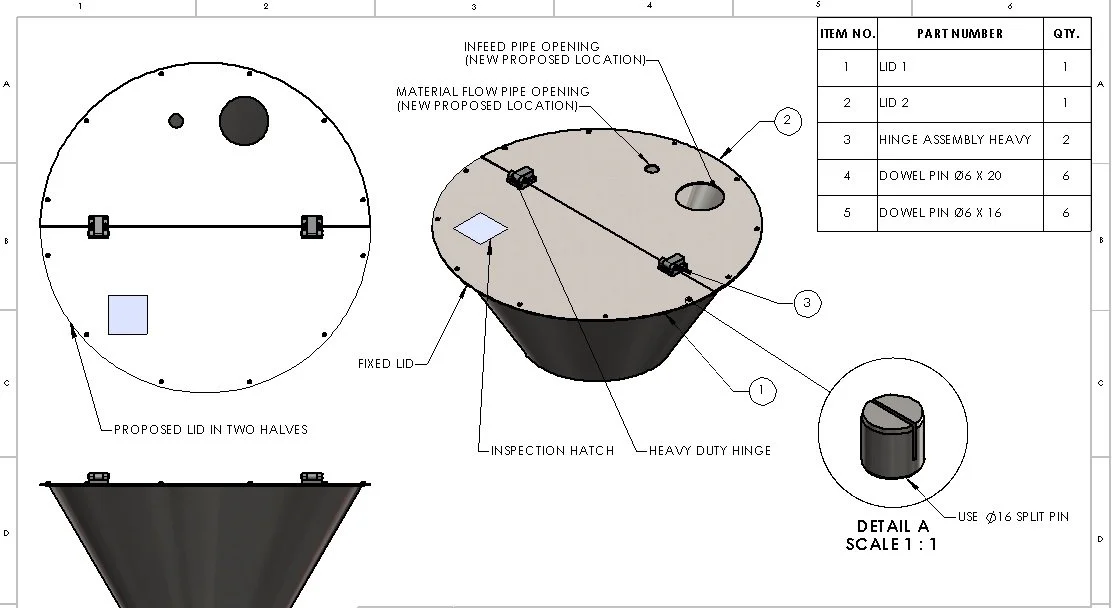

Using advanced 3D CAD modelling, we visualised the plant environment in detail, simulating maintenance workflows and identifying potential hazards early. This iterative process allowed us to refine the concept with precision, ensuring seamless integration into the existing setup.

The Solution

The final concept balanced innovation, durability, and ease of use. Core design features included:

Modular Construction

Detachable sections simplified installation and future maintenance, reducing disruption and enabling fast component replacement.

Durable, Industrial-Grade Materials

We selected high-strength, corrosion-resistant materials suited to constant exposure to dust, moisture, and vibration.

Improved Accessibility

Ergonomic handles and strategically placed access points enabled safer, more comfortable maintenance activities.

Integrated Safety Features

Built-in guards and sensor provisions were included to allow machinery to automatically shut down if the cover was opened—adding a proactive layer of protection.

The design was engineered to fit effortlessly into the plant’s infrastructure with minimal changes required—an essential consideration for continuous manufacturing operations.

Projected Benefits

While the project did not move to implementation, our analysis demonstrated the potential impact:

Reduced Injuries: Key hazards effectively eliminated, enhancing worker safety.

Greater Efficiency: Streamlined maintenance access and modular parts reducing downtime.

Compliance Ready: Designed in alignment with relevant Australian safety standards.

Client feedback during development highlighted the strength of our methodology, attention to detail, and practical understanding of maintenance requirements.

What We Learned

This project provided valuable insights into the unique operational pressures within pet food manufacturing. Collaboration with MNA Solutions and plant personnel strengthened our ability to convert frontline challenges into efficient, safety-focused design outcomes.

It also cemented our continued investment in 3D modelling and simulation as essential tools in our workflow—helping us deliver more accurate, risk-aware design solutions.

Conclusion

The Hopper Cover Design Project remains a strong example of our dedication to safety, innovation, and meaningful collaboration. Even without final deployment, it reflects the high level of thought, engineering rigour, and client focus that defines KEVOS®.

As we continue to grow, we bring these lessons and capabilities to every new challenge—working to create safer, smarter workplaces across all industries.

Need Engineering Design & Drafting Support?

Whether you're improving an existing facility or planning a new installation, our team is ready to help.

Contact KEVOS® today to discuss how we can support your next engineering challenge.