A Journey from Chaos to Excellence

In the high-stakes world of modern manufacturing, where a single defective component can ground an aircraft or recall thousands of vehicles, there exists a guardian process that stands between potential disaster and engineering excellence123. This guardian is the Production Part Approval Process (PPAP), and its story is one of transformation, innovation, and the relentless pursuit of quality that has reshaped entire industries45.

Imagine, for a moment, the automotive industry of the 1980s13. Suppliers operated in relative isolation, manufacturing parts based on drawings and specifications, but with little systematic verification that their processes could consistently deliver the required quality67. Quality issues were discovered late in the process, often after parts had already been shipped to customers, resulting in costly recalls and damaged reputations89. It was against this backdrop of quality uncertainty that the Automotive Industry Action Group (AIAG) developed PPAP—a revolutionary approach that would fundamentally change how industries ensure quality and reliability12.

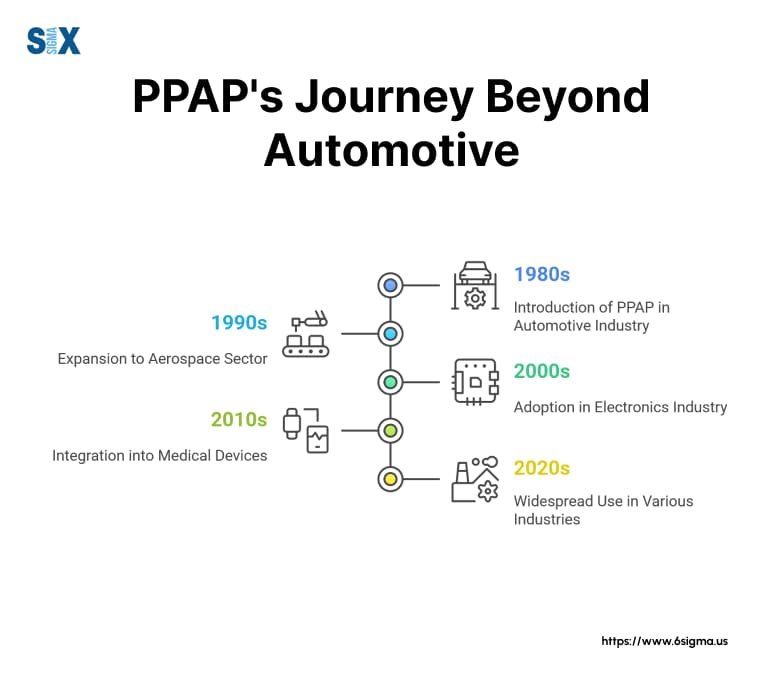

PPAP’s Journey Beyond Automotive: From automotive to aerospace, electronics, and medical devices, PPAP has seen widespread use across various industries6sigma

The Genesis of a Quality Revolution

The story of PPAP begins with a simple yet profound realization: prevention is infinitely more valuable than correction1720. In the traditional manufacturing paradigm, quality was often an afterthought—something to be inspected rather than built into the process1415. The cost of poor quality in manufacturing typically ranges from 15-40% of revenue, representing an enormous opportunity for improvement172023.

PPAP emerged as a standardized methodology that fundamentally shifted the quality paradigm from reactive to proactive1216. Rather than discovering problems after production, PPAP requires suppliers to demonstrate their capability before mass production begins1318. This seemingly simple shift has generated remarkable results: companies implementing robust quality management systems, including PPAP, have seen an average return of $6 in revenue for every $1 invested2023.

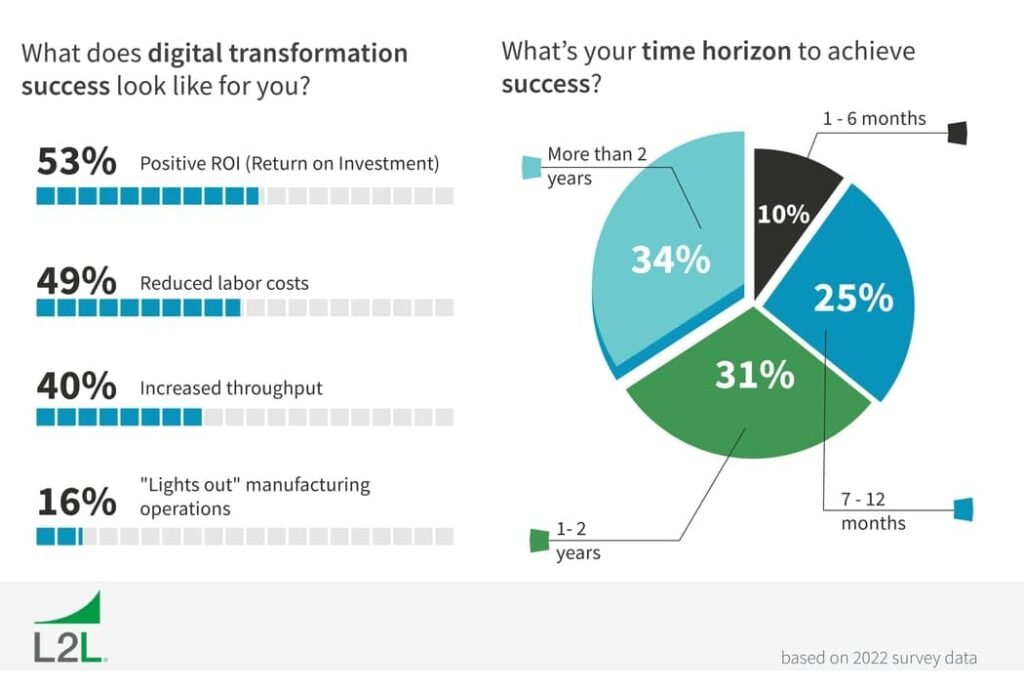

Survey Results On The Outcomes And Time Horizon For Digital Transformation Successl2l

The Evolution of Excellence: From Manual to AI-Enhanced

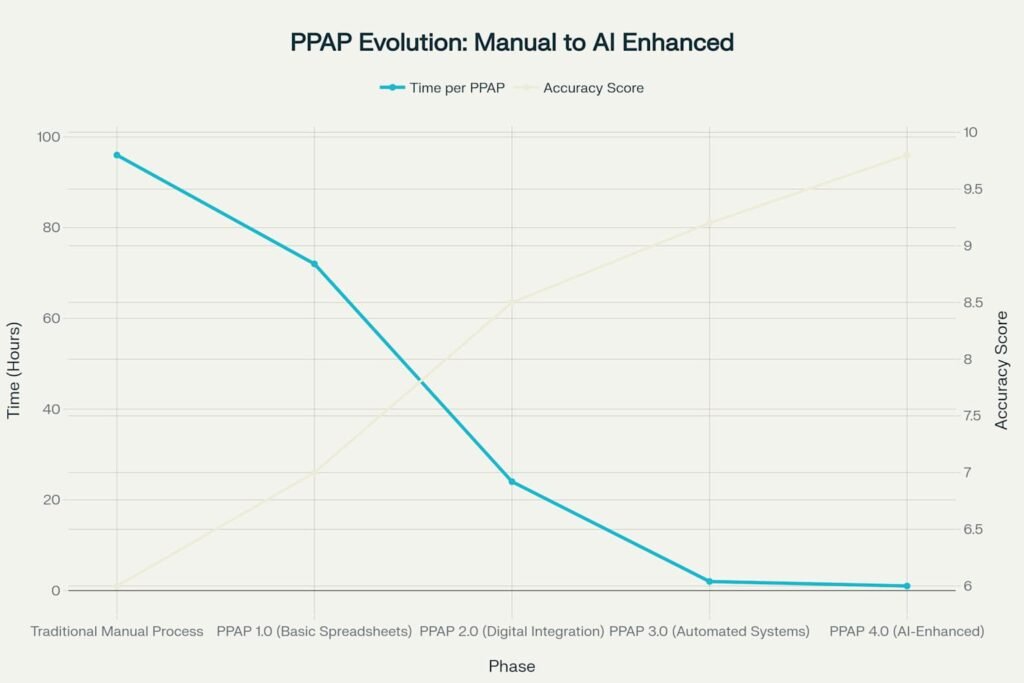

The journey of PPAP implementation has been one of continuous evolution, marked by dramatic improvements in both efficiency and accuracy1922. Traditional manual PPAP processes once required up to 96 hours of labor per submission, with accuracy scores hovering around 6.0 on a 10-point scale1922. Today, AI-enhanced PPAP systems can complete the same process in just one hour with accuracy scores exceeding 9.8151922.

PPAP Implementation Evolution: Transformation from Manual Processes to AI-Enhanced Systems

This transformation didn’t happen overnight. It represents decades of technological advancement and process refinement8913. The evolution from PPAP 1.0 (basic spreadsheets) to PPAP 4.0 (AI-enhanced systems) has delivered efficiency gains of up to 4,200%, fundamentally changing how engineering firms approach quality documentation151922.

The Eighteen Pillars of Quality: Understanding PPAP Elements

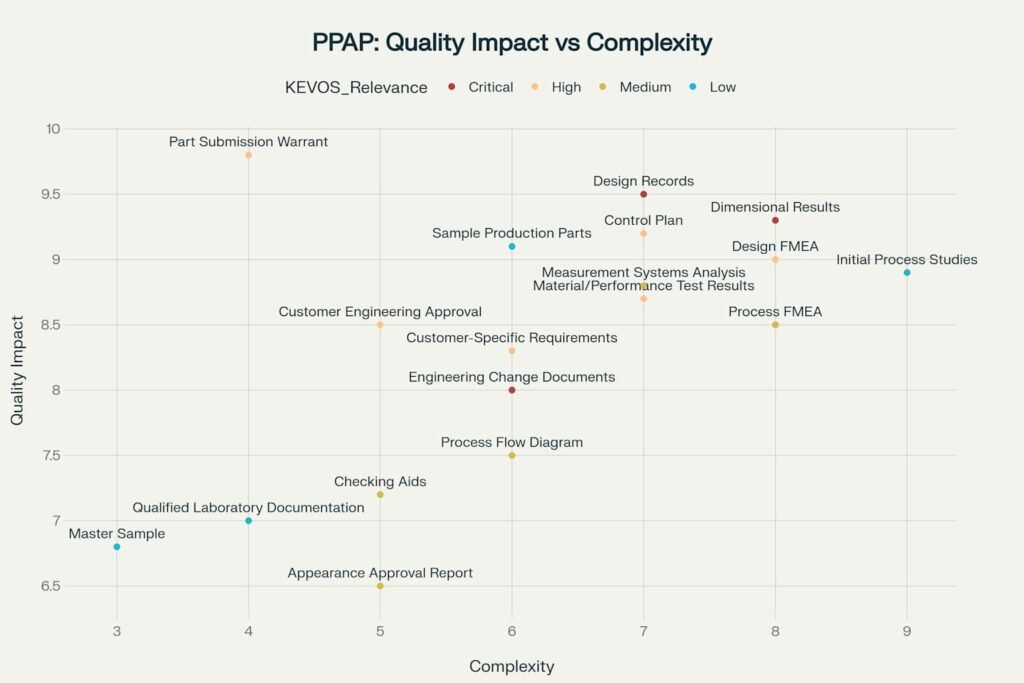

At the heart of PPAP lies a comprehensive framework of 18 elements, each serving as a critical pillar in the architecture of quality assurance123. These elements range from design records and engineering change documentation to dimensional results and part submission warrants1316. However, not all elements carry equal weight for every organization—particularly for engineering design and drafting service providers like KEVOS812.

PPAP Elements Analysis: Relationship between Quality Impact and Implementation Complexity

The relationship between quality impact and implementation complexity varies significantly across the 18 PPAP elements812. For engineering firms, elements such as Design Records, Engineering Change Documents, and Dimensional Results represent critical, high-impact areas that directly align with their core competencies1312. These elements not only deliver the highest quality improvements but also provide the greatest opportunity for engineering firms to differentiate themselves in the marketplace81221.

Real-World Transformation: The J&L Manufacturing Success Story

To understand the true power of PPAP implementation, consider the remarkable transformation of J&L Manufacturing, an ISO 9001 certified job shop specializing in complex CNC machining and metal fabrication19. Christy Wiggam, the company’s quality manager, faced a daunting challenge: PPAP submissions that consumed an entire week of effort, creating a significant bottleneck that limited the company’s ability to accept new business19.

The traditional process was painfully manual1922. Christy would take paper copies of customer prints, mark each dimension with yellow stickers, scan drawings into her computer, and manually type each dimension into Excel templates19. The creation of Process FMEAs, control plans, and process flows followed the same laborious pattern1922. This approach not only consumed precious time but also introduced opportunities for human error1119.

The transformation came through digital integration and process automation101922. By implementing modern PPAP management software, J&L Manufacturing achieved a remarkable outcome: Christy now completes over 168 PPAPs annually—more than one per day on average19. This represents a productivity improvement that seemed impossible under the old manual system1922.

Several colorful gears are arranged to interlock, symbolizing teamwork and interconnectednesscvgstrategy

The Financial Reality: PPAP’s Return on Investment

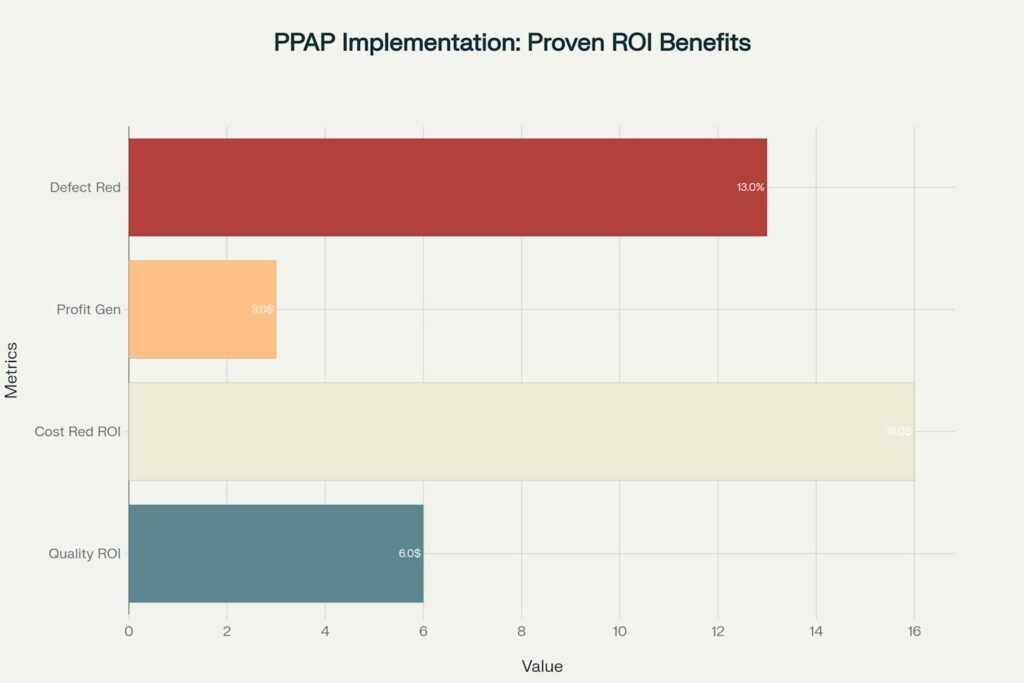

The financial benefits of PPAP implementation extend far beyond time savings151720. Research consistently demonstrates that quality management initiatives, including PPAP, generate substantial returns across multiple dimensions2023. Companies implementing comprehensive quality programs see an average of $16 in cost reduction for every dollar invested2023.

PPAP ROI Metrics: Demonstrating the Financial and Quality Benefits of Implementation

The specific benefits of PPAP implementation are particularly compelling for the automotive and aerospace industries4621. Supplier defect rates can be reduced by as much as 13%, while process time improvements can reach extraordinary levels—in some cases exceeding 4,000% efficiency gains192122. These improvements translate directly to bottom-line benefits: reduced warranty costs, fewer recalls, improved customer satisfaction, and enhanced competitive positioning41721.

Digital Transformation: The Modern PPAP Landscape

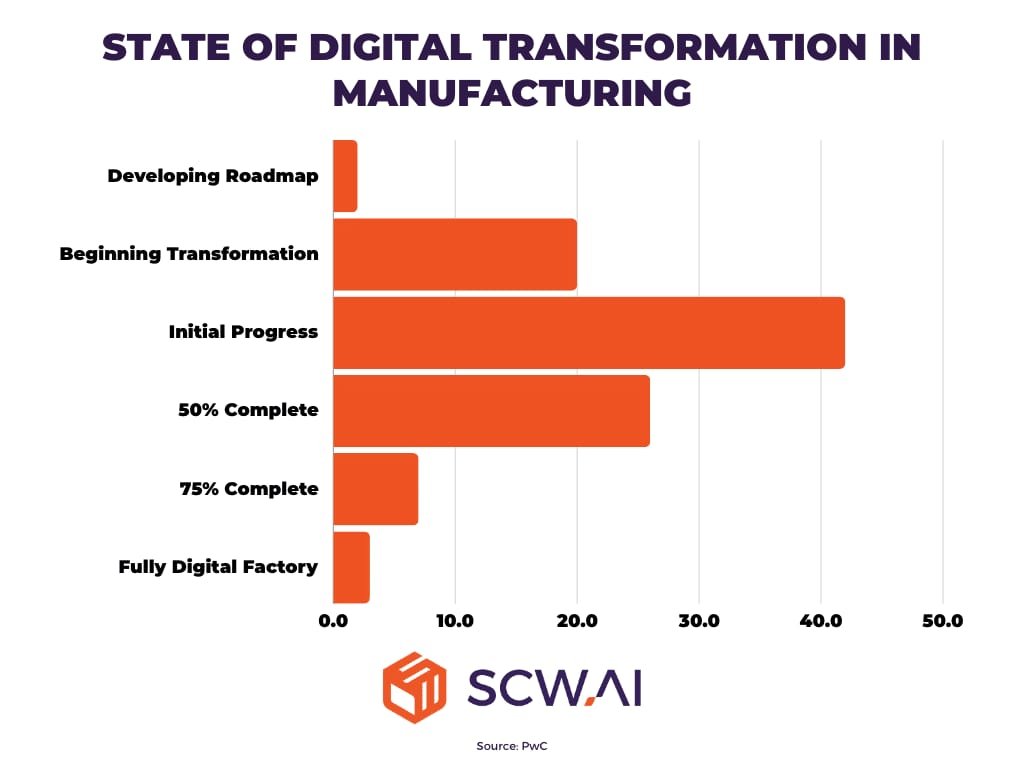

Today’s manufacturing environment is characterized by rapid digital transformation, with companies at various stages of their quality digitization journey141517. Current research indicates that 42% of manufacturers are in the initial progress stage of digital transformation, while only a small percentage have achieved fully digital factory status17. This presents both a challenge and an opportunity for engineering firms seeking to leverage PPAP for competitive advantage81415.

State of digital transformation in manufacturing, indicating progress levelsscw

The benefits of digital transformation in manufacturing are well-documented and substantial1415. Modern PPAP implementations deliver increased efficiency, quality improvement, improved customer experience, reduced costs, and enhanced digital culture15. These benefits align perfectly with the core objectives of PPAP: ensuring consistent quality while optimizing process efficiency1315.

Benefits of Digital Transformation in Manufacturingeffectivesoft

The KEVOS Advantage: Strategic PPAP Implementation

For engineering design and drafting service providers like KEVOS, understanding and implementing PPAP represents more than just compliance—it’s a strategic differentiator that opens doors to new markets and strengthens client relationships812. The key lies in recognizing which PPAP elements offer the greatest opportunity for value creation812.

Design Records represent perhaps the most critical element for engineering firms138. These comprehensive drawings and specifications form the foundation of the entire PPAP process13. When KEVOS provides accurate, detailed drawings with clearly marked special characteristics and comprehensive dimensional information, it directly supports multiple downstream PPAP elements812. This foundational work reduces the risk of nonconformance and accelerates the approval process1321.

Engineering Change Management constitutes another area of critical importance138. In today’s dynamic manufacturing environment, design changes are inevitable13. KEVOS’s expertise in documenting and communicating these changes through clear Engineering Change Notices ensures traceability and maintains approval status throughout the product lifecycle138.

Technical drawing with cross-sectional, front, and isometric views, including dimensions and annotationshlhrapid

Overcoming Implementation Challenges

The path to successful PPAP implementation is not without obstacles11. Common challenges include insufficient technology infrastructure, demanding time and resource requirements, and capability gaps within organizations11. Many companies struggle with too many documents and insufficient document control, making it difficult to standardize procedures across global supply chains11.

However, these challenges are not insurmountable918. Best practices for PPAP implementation include establishing clear and concise requirements, creating comprehensive PPAP packages, utilizing specialized software solutions, training employees on procedures, and maintaining effective customer communication918. The key is approaching implementation systematically, with adequate planning and resource allocation918.

Seven Strategies For Successful Project Collaborationproofhub

The Future of PPAP: Industry 4.0 and Beyond

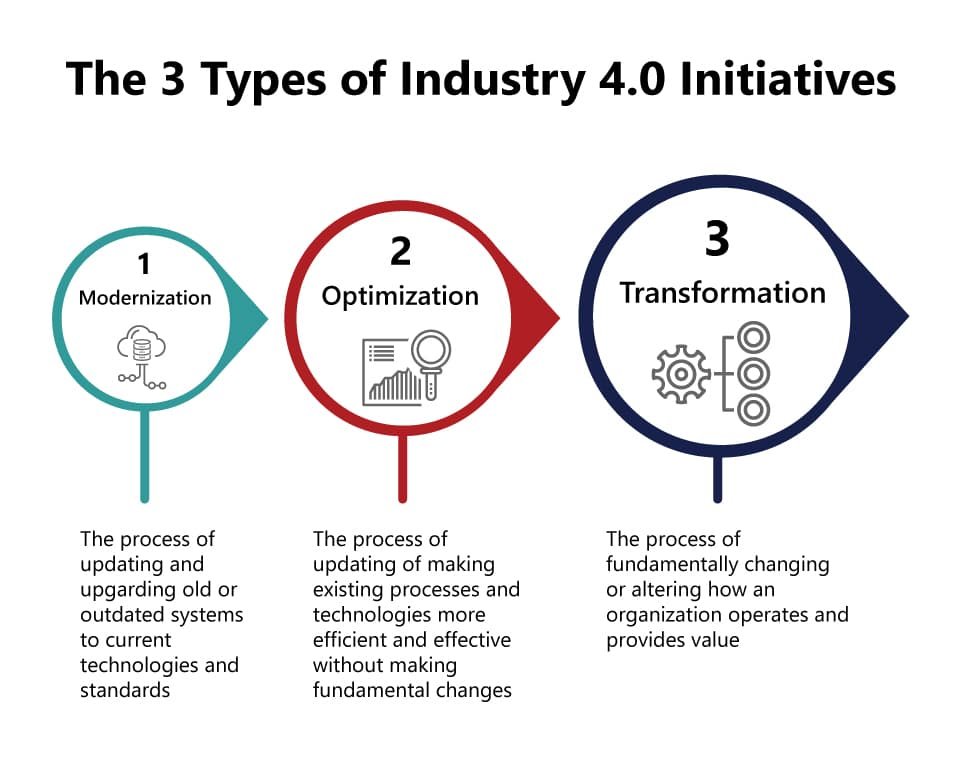

The future of PPAP lies in the convergence of traditional quality management principles with cutting-edge digital technologies131519. Industry 4.0 initiatives—encompassing modernization, optimization, and transformation—are reshaping how manufacturers approach quality assurance1920. Artificial intelligence, machine learning, and advanced analytics are being integrated into PPAP processes to deliver unprecedented levels of efficiency and accuracy151922.

The 3 Types of Industry 4.0 Initiatives Include Modernization, Optimization, and Transformationhitachi-solutions

This technological evolution doesn’t diminish the importance of fundamental PPAP principles; rather, it amplifies their impact131519. Digital tools enable more sophisticated analysis, faster processing, and greater accuracy, but the underlying need for systematic quality validation remains constant1315.

A Roadmap for Success: Implementing PPAP Excellence

For engineering firms ready to embrace PPAP as a strategic advantage, success requires a structured approach.

PPAP Implementation Roadmap for Engineering Firms

Phase 1: Foundation Building (Weeks 1-4)

Week 1-2: Assessment and Planning

- Conduct PPAP Readiness Assessment

- Evaluate current design documentation practices

- Assess team knowledge of PPAP requirements

- Review existing quality management systems

- Identify gaps in processes and capabilities

- Develop Implementation Strategy

- Define PPAP objectives and success metrics

- Allocate resources and assign responsibilities

- Create project timeline and milestones

- Establish budget for training and tools

Week 3-4: Team Preparation

- PPAP Training Program

- AIAG PPAP manual review sessions

- Industry-specific requirements training

- Software tools familiarization

- Best practices workshops

- Process Documentation

- Map current design workflow

- Identify PPAP integration points

- Create standardized templates

- Establish quality checkpoints

Phase 2: System Integration (Weeks 5-8)

Week 5-6: Technology Setup

- Digital Infrastructure

- Implement PPAP management software

- Set up document control systems

- Configure automated workflows

- Integrate with existing CAD systems

- Quality Management Integration

- Link PPAP requirements to design processes

- Establish measurement systems

- Create reporting dashboards

- Set up customer collaboration portals

Week 7-8: Process Standardization

- Design Documentation Standards

- Update drawing templates for PPAP compliance

- Standardize special characteristics marking

- Implement change control procedures

- Create design review checklists

- Communication Protocols

- Establish customer interaction procedures

- Create submission tracking systems

- Develop escalation processes

- Set up regular review meetings

Phase 3: Pilot Implementation (Weeks 9-12)

Week 9-10: Pilot Project Selection

- Project Criteria

- Select low-risk, representative projects

The implementation journey typically spans 16 weeks, progressing through four distinct phases: Foundation Building, System Integration, Pilot Implementation, and Full Deployment.

The Foundation Building phase focuses on assessment and preparation, ensuring that the organization has the necessary knowledge, processes, and infrastructure to support PPAP implementation. This includes conducting readiness assessments, developing implementation strategies, and establishing comprehensive training programs9.

System Integration involves implementing the technological infrastructure necessary for modern PPAP management10. This includes digital document control systems, automated workflows, and integration with existing CAD systems1015. The goal is creating a seamless environment where PPAP requirements are naturally embedded in existing design processes15.

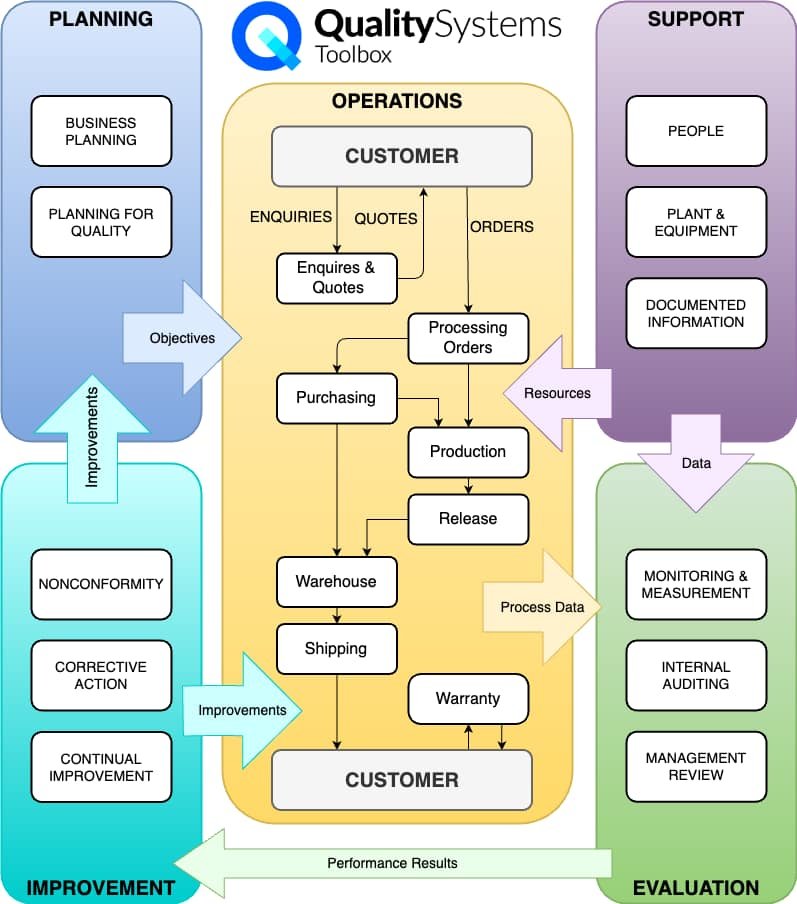

Process Map Showing Interplay Between Business Functions In A Quality Management Systemqualitysystems

The Continuous Improvement Imperative

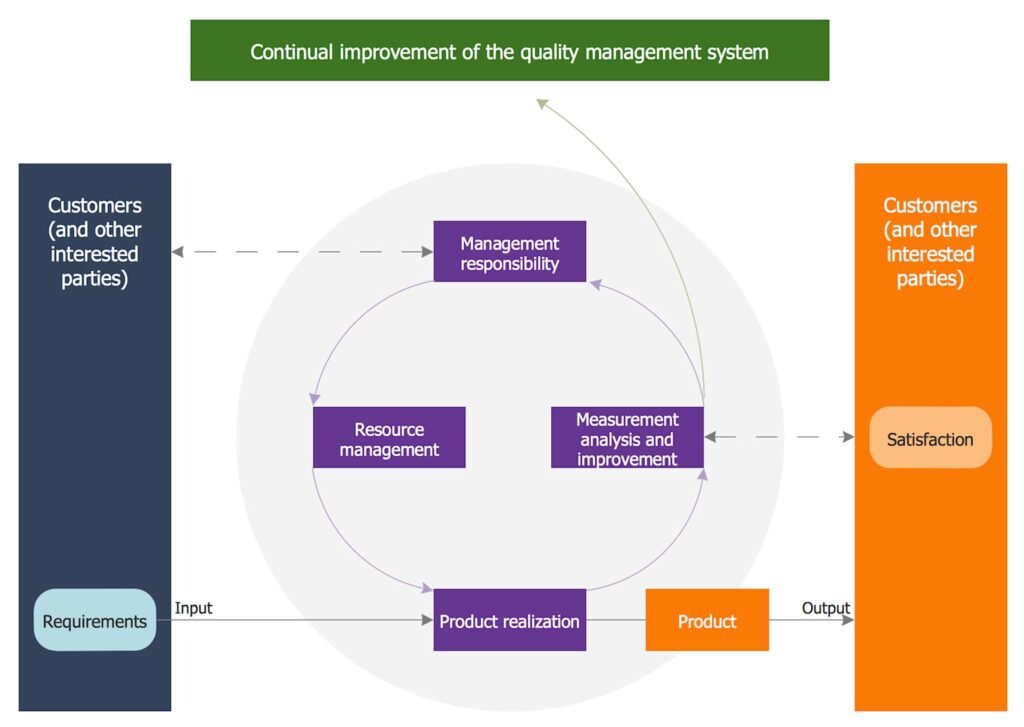

PPAP implementation is not a destination but a journey of continuous improvement147. The most successful organizations treat PPAP as part of a broader quality management system that encompasses planning, operations, support, evaluation, and improvement714. This holistic approach ensures that quality remains a central focus throughout the entire product lifecycle714.

Process Flowchart Illustrating a Quality Management Systemconceptdraw

The integration of PPAP with Six Sigma methodologies and other quality management frameworks creates powerful synergies714. Statistical Process Control, Measurement System Analysis, and Failure Mode and Effects Analysis all contribute to the robustness of the PPAP process714. When these tools work in concert, they create a comprehensive quality ecosystem that dramatically reduces the risk of defects and nonconformance71421.

Success Stories: PPAP in Action

The real-world impact of PPAP implementation can be seen across numerous industry success stories4619. Tier 1 automotive suppliers have leveraged PPAP expertise to manage thousands of suppliers globally, achieving on-time deliveries and maintaining relationships with major OEMs like Tesla, Ford, and GM46. These successes demonstrate that PPAP is not merely a compliance requirement but a strategic capability that drives business growth4621.

In the aerospace industry, fastener manufacturers have used PPAP to validate complex supply chains and ensure compliance with stringent quality requirements6. The systematic approach of PPAP provides the documentation and verification necessary to meet the demanding standards of aerospace applications616.

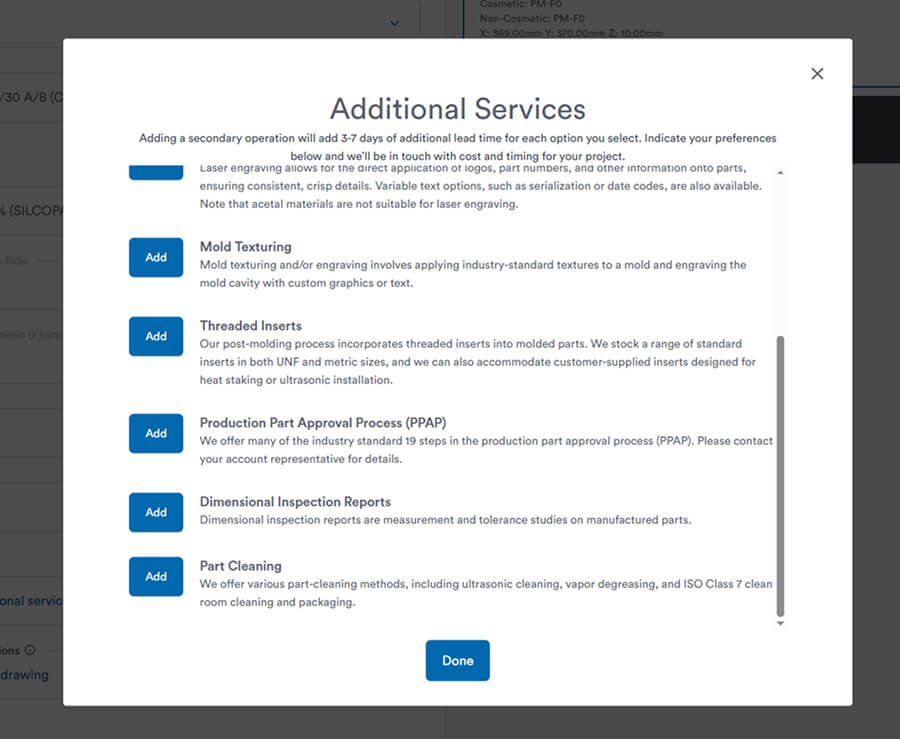

A list of additional manufacturing services, including PPAPprotolabs

The Collaborative Foundation

At its core, PPAP success depends on effective collaboration between suppliers, customers, and engineering service providers1118. The process requires clear communication, shared understanding of requirements, and commitment to continuous improvement1118. For engineering firms like KEVOS, this collaborative approach creates opportunities to add value beyond traditional design services81118.

The evolution of PPAP from its automotive origins to widespread adoption across industries demonstrates the universal applicability of its principles1316. Whether in aerospace, electronics, medical devices, or other precision manufacturing sectors, the fundamental need for systematic quality validation remains constant131624.

Measuring Success: Key Performance Indicators

The success of PPAP implementation must be measured across multiple dimensions21. Quality metrics include submission approval rates (targeting >95% first-time approval), customer satisfaction scores (>90%), defect reduction (50% improvement), and compliance rates (100% PPAP compliance)21. These metrics provide objective measures of PPAP effectiveness21.

Efficiency metrics focus on time and resource optimization19. Successful implementations typically achieve 60% reduction in PPAP preparation time, 40% improvement in resource utilization, 50% decrease in preparation costs, and 25% improvement in overall project delivery1922. These improvements directly impact profitability and competitive positioning1920.

Business impact metrics capture the broader strategic value of PPAP capabilities20. Organizations typically see 30% increase in PPAP-related business, expanded market share in regulated industries, >95% customer retention rates, and enhanced competitive differentiation2023.

The Global Perspective: PPAP’s Worldwide Impact

The influence of PPAP extends far beyond its American automotive origins13. The process has been adapted and adopted globally, with variations like the German VDA’s Production Process and Product Approval (PPA/PPF) serving similar functions in European markets13. This global standardization has facilitated international trade and collaboration, creating a common language for quality assurance across borders1316.

The digitalization of both PPAP and PPA/PPF processes has further accelerated global adoption13. Cloud-based systems enable real-time collaboration between suppliers and customers regardless of geographic location1013. This technological enablement has made it possible for engineering firms to serve global markets more effectively101315.

Conclusion: The Strategic Imperative

Understanding PPAP is indeed the key to quality in engineering production, but it represents something far more significant than a compliance requirement123. PPAP embodies a fundamental shift in how organizations approach quality—from reactive inspection to proactive prevention, from isolated processes to integrated systems, from manual documentation to digital transformation1315.

For engineering design and drafting firms like KEVOS, mastering PPAP opens doors to new markets, strengthens client relationships, and creates sustainable competitive advantages812. The firms that embrace PPAP as a strategic capability—rather than viewing it as a burden—will find themselves well-positioned to thrive in an increasingly quality-conscious global marketplace81221.

The journey from chaos to excellence is not always smooth, but the destination is worth the effort1922. As manufacturing continues to evolve toward Industry 4.0 and beyond, the principles embodied in PPAP—systematic validation, continuous improvement, and collaborative excellence—will remain constant151920. Organizations that understand and implement these principles today will be the quality leaders of tomorrow152023.

The story of PPAP is ultimately a story of transformation—of industries, organizations, and individuals committed to the pursuit of excellence131922. In a world where quality is not just desired but demanded, understanding PPAP is not just beneficial—it’s essential1324. The question is not whether to implement PPAP, but how quickly and effectively it can be done8918. The future of quality engineering depends on the answer152024.

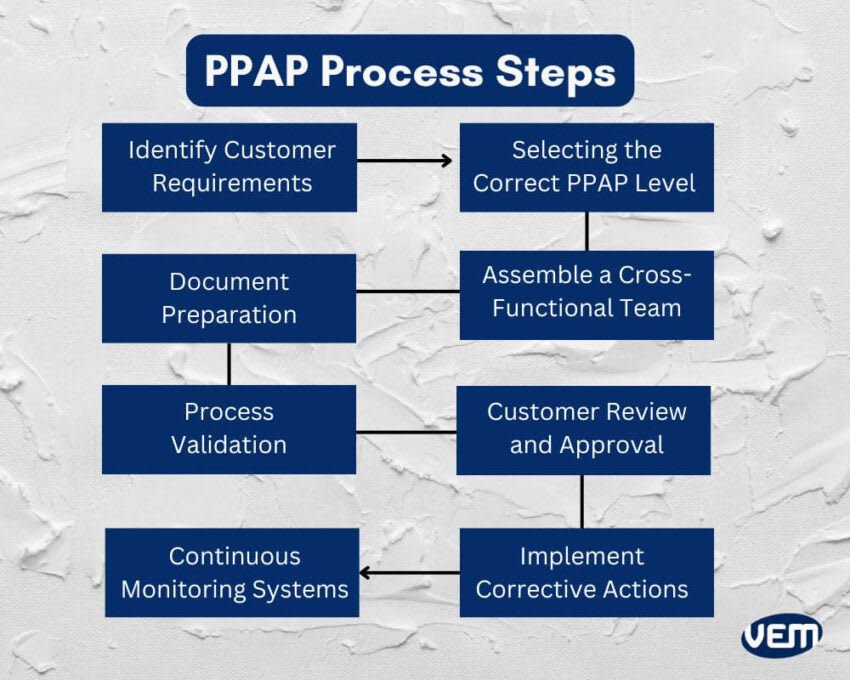

Flowchart illustrating the PPAP process stepsvem-tooling

The path forward is clear: embrace PPAP as both a methodology and a mindset, leverage technology to amplify its benefits, and commit to the continuous improvement that lies at its heart1715. In doing so, engineering firms will not just meet today’s quality requirements—they will help define tomorrow’s standards of excellence81524.

- https://www.discussoftware.com/tips/ppap-requirements-2024-guide/

- https://quality-one.com/ppap/

- https://www.handicaregroup.com/inc/uploads/2024/04/PPAP-Completing-Documentation-Training-Material.pdf

- https://www.empowerqlm.com/case-studies/apqp-activities-ppap-approvals/

- https://www.linkedin.com/pulse/overcoming-objections-apqp-ppap-deployment-john-m-cachat-fwm1e

- https://www.empowerqlm.com/case-studies/ppap-approvals-for-fasteners/

- https://www.6sigma.us/six-sigma-in-focus/production-part-approval-process-ppap/

- https://ppapmanager.com/2023/09/4-key-strategies-ppap-management-2023-2024/

- https://ppapmanager.com/2023/08/good-practices-ppap-processes/

- https://praxie.com/production-part-approval-process-app-software-manufacturing/

- https://www.empowerqlm.com/common-ppap-pain-points/

- https://www.linkedin.com/pulse/understanding-ppap-comprehensive-guide-mechanical-design-nayak-wqs3f

- https://en.material.one/news-und-fachartikel/unterschiede-pff-und-ppap-beide-verfahren-digitalisieren

- https://www.linkedin.com/pulse/understanding-relationship-between-ppap-rest-core-quality-0az9c

- https://www.linkedin.com/pulse/ppap-20-required-get-any-roi-john-m-cachat-lcs5f

- https://leanmanufacturing.online/ensuring-quality-in-the-automotive-industry-with-ppap/

- https://www.symestic.com/en-us/what-is/cost-of-poor-quality

- https://www.colabsoftware.com/ppap-implementation-guide

- https://www.linkedin.com/pulse/case-study-how-one-person-creates-5-ppaps-week-using-1factory-3eqic

- https://www.simpleque.com/whats-the-roi-of-quality/

- https://www.cority.com/blog/ppap-documentation/

- https://my.omnex.com/casestudies/case-study-automating-ppap-documentation

- https://www.etq.com/blog/5-stats-on-the-roi-of-quality-as-a-strategic-business-initiative/

- https://safetyculture.com/topics/ppap/

- https://ppapmanager.com/2024/06/supplier-categorization/

- https://www.gore.com/resources/gore-automotive-vents-ppap-an-overview

- https://www.amazon.com.au/Production-Part-Approval-Process-PPAP/dp/B004Z0VB68

- https://intellaquest.com/overcoming-common-ppap-challenges-that-lead-to-oem-rejections/

- https://www.capvidia.com/blog/ppap-guide

- https://www.aiag.org/training-and-resources/manuals/details/PPAP-4

- https://www.chaintraced.com/posts/what-is-ppap-why-is-it-important-and-what-are-the-challenges

- https://www.omnexsystems.com/case-study/apqp-ppap-documentation-solution-for-a-leading-tier-1-automotive-supplier