From Chaos to Control

Picture this: It’s 3 AM, and Sarah, a mechanical engineer at a growing manufacturing company, is frantically searching through hundreds of CAD files on her computer1. Her team’s latest project—a complex automated assembly line—has grown to over 2,000 parts, and nobody knows which version of the critical bearing housing is the current one9. Three different engineers have been working on similar components, each saving files with slightly different names, and now the assembly won’t open because half the references are missing10. Sound familiar? This nightmare scenario plays out in engineering departments worldwide, but it doesn’t have to be your story1.

The difference between engineering success and disaster often comes down to one critical factor that many teams overlook until it’s too late: proper planning and file management1. When SolidWorks projects grow beyond a few dozen parts, the complexity can quickly overwhelm even the most experienced engineers4. Without proper planning and file management systems, teams face lost data, sluggish performance, skyrocketing costs, and projects that grind to a halt just when deadlines loom largest1.

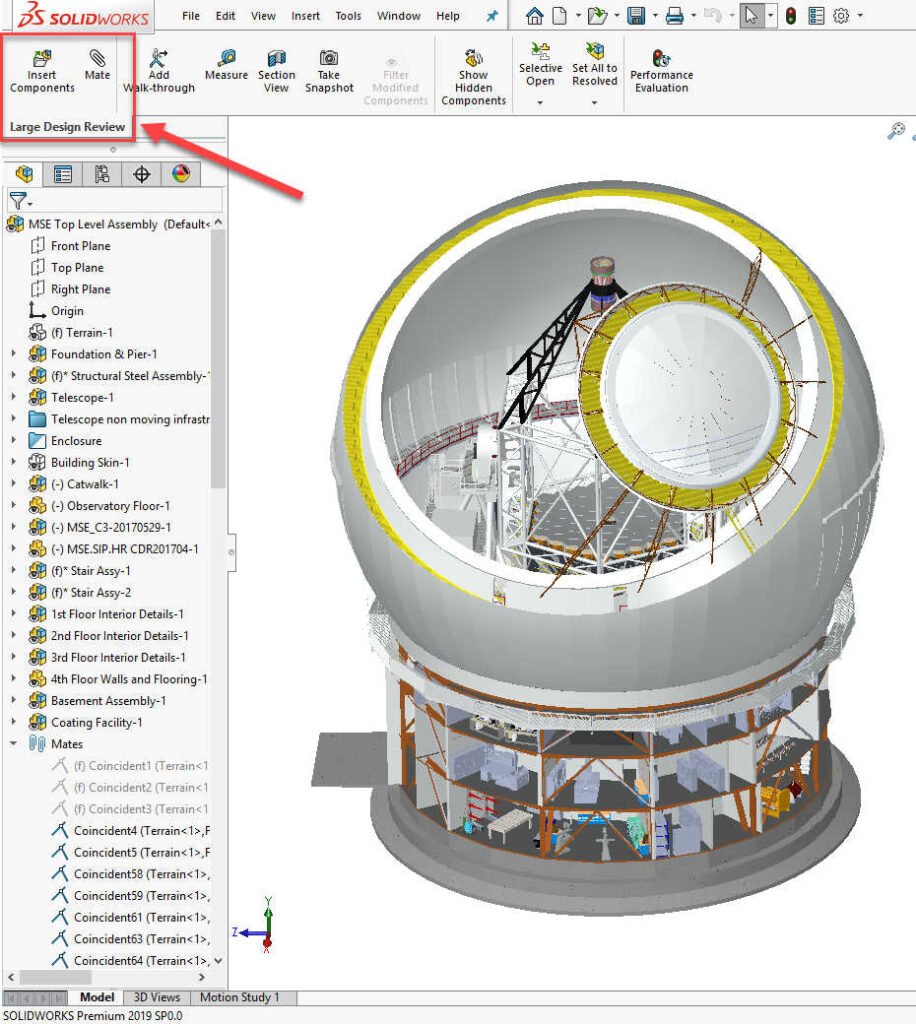

SolidWorks Interface Showing a Complex Assembly Model in Large Design Review Modesolidworks

The Hidden Cost of Poor File Management

Let’s dive deeper into Sarah’s world to understand the true impact of inadequate file management. Her company started small, with just three engineers working on simple products9. Back then, storing files in a shared network folder seemed sufficient10. Everyone knew where everything was, and conflicts were rare15. But as the company grew and projects became more complex, this simple approach began to crack under pressure9.

The data tells a sobering story about the real cost of poor file management practices. Organizations using manual file management approaches lose an average of 11.67 hours per week to file-related issues.

Solidworks Management Analysis

| Management_Approach | Project_Size | Time_Lost_Per_Week_Hours | Data_Loss_Risk_Percent | Collaboration_Efficiency_Score | Setup_Cost_USD | Annual_Maintenance_Cost_USD | Annual_Time_Lost_Hours | Annual_Cost_of_Lost_Time_USD | Total_Annual_Cost_USD |

|---|---|---|---|---|---|---|---|---|---|

| Manual File Management | Small (< 100 parts) | 2.0 | 15 | 3 | 0 | 0 | 104.0 | 7800.0 | 7800.0 |

| Manual File Management | Medium (100-1000 parts) | 8.0 | 35 | 2 | 0 | 0 | 416.0 | 31200.0 | 31200.0 |

| Manual File Management | Large (> 1000 parts) | 25.0 | 60 | 1 | 0 | 0 | 1300.0 | 97500.0 | 97500.0 |

| SolidWorks Workgroup PDM | Small (< 100 parts) | 1.0 | 5 | 7 | 2000 | 500 | 52.0 | 3900.0 | 4400.0 |

| SolidWorks Workgroup PDM | Medium (100-1000 parts) | 3.0 | 10 | 8 | 3000 | 800 | 156.0 | 11700.0 | 12500.0 |

| SolidWorks Workgroup PDM | Large (> 1000 parts) | 8.0 | 20 | 7 | 5000 | 1200 | 416.0 | 31200.0 | 32400.0 |

| SolidWorks Enterprise PDM | Small (< 100 parts) | 0.5 | 1 | 9 | 10000 | 2000 | 26.0 | 1950.0 | 3950.0 |

| SolidWorks Enterprise PDM | Medium (100-1000 parts) | 1.0 | 2 | 9 | 15000 | 3000 | 52.0 | 3900.0 | 6900.0 |

| SolidWorks Enterprise PDM | Large (> 1000 parts) | 2.0 | 5 | 10 | 25000 | 5000 | 104.0 | 7800.0 | 12800.0 |

For large projects exceeding 1,000 parts, this jumps to a staggering 25 hours per week—more than half of a full-time engineer’s productivity lost to searching for files, resolving conflicts, and recreating lost work. When you factor in the average engineering hourly rate of $75, these inefficiencies cost organizations using manual approaches an average of $45,500 annually in lost productivity alone.

But the financial impact extends far beyond lost time. Poor file management creates a cascade of problems that ripple through entire organizations12. Data loss risks climb to 60% for large manual projects, meaning teams face a significant chance of losing critical design work. Collaboration efficiency plummets as engineers struggle to coordinate changes, often working on outdated versions or duplicating efforts11. Projects experience delays, quality suffers, and customer satisfaction erodes14.

Consider the real-world example of HemoSonics, a biotech company developing blood analysis systems11. Engineers Andy Homyk and Tim Higgins found themselves “lost in a sea of unmanaged CAD files” when their mechanical engineering department grew beyond its original three-person team11. They resorted to passing USB drives back and forth to transfer files—a time-consuming process that made version control nearly impossible and left them constantly worried about having the most current designs11.

The Foundation: Strategic Planning Before You Start

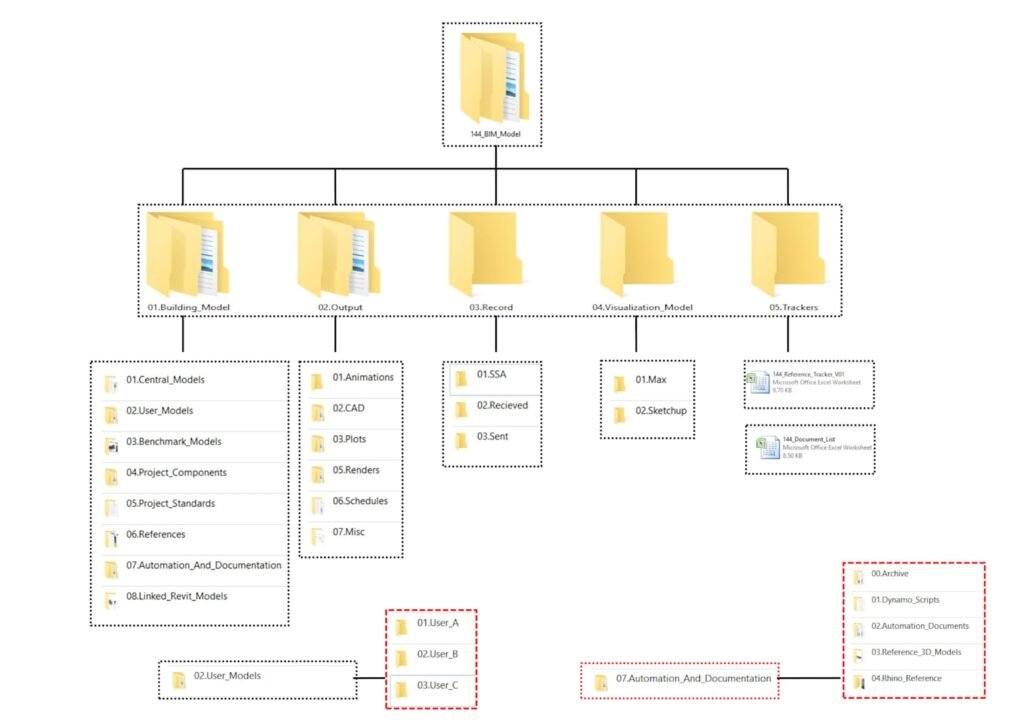

Folder hierarchy structure for organizing CAD and BIM project fileswordpress

The most successful SolidWorks implementations begin long before the first part is modeled1. Just as a construction project requires detailed architectural plans before ground is broken, large SolidWorks assemblies demand comprehensive planning to ensure success1. This planning phase involves understanding your project scope, selecting appropriate modeling techniques, establishing file naming conventions, and choosing the right data management approach2.

Understanding Project Scope and Complexity

The first step in any large SolidWorks project is conducting a thorough scope assessment1. Teams must estimate the total number of parts expected, identify key assemblies and sub-assemblies, and determine the complexity level of their designs2. A consumer electronics product with intricate curved surfaces requires different planning than an industrial machine with primarily geometric components1.

Project complexity isn’t just about part count—it’s about relationships, dependencies, and the collaborative workflows required to bring designs to life4. A manufacturing plant layout might contain fewer individual parts than a smartphone, but the interconnected systems, spatial relationships, and multi-disciplinary coordination requirements create different challenges6.

Choosing Your Modeling Strategy

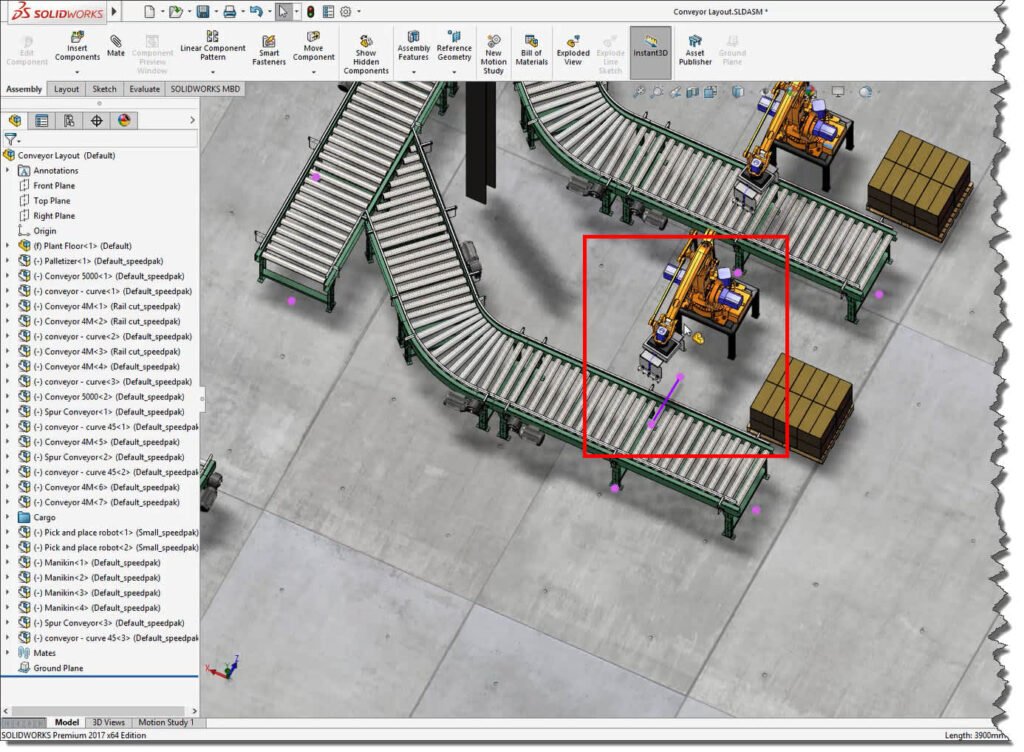

SolidWorks offers two primary techniques for managing large assemblies, each suited to different types of projects1. The skeleton model technique works best for machines, plants, and paper processing equipment where you need to visualize and select important interfaces at all sub-assembly and part levels6. This approach creates a structural framework that guides component placement and ensures proper fit throughout the design19.

An automated conveyor system designed in SolidWorkssolidworks

The master model technique, conversely, suits consumer products like automotive bodies, ducts, and appliances where complex surfaces serve as the foundation for multiple components1718. This method results in multi-body parts that share common boundaries and surfaces, allowing changes to propagate efficiently through related components24. When engineers modify the master model, derived parts update automatically, maintaining design consistency across the entire product20.

File Naming and Revision Control

Establishing clear file naming conventions might seem trivial, but it forms the backbone of effective file management2. Teams must decide between intelligent part numbering systems that embed meaning in the filename versus simpler sequential numbering approaches1. Each method has merits: intelligent numbering helps engineers quickly understand component functions, while sequential numbering avoids confusion when parts change purpose during development15.

Revision control requires equal attention to detail3. Teams need clear schemes for tracking changes—whether alphabetic, numeric, or hybrid approaches—and consistent workflows for capturing revisions in filenames and metadata1. Without proper revision control, engineers lose track of design evolution and risk implementing outdated changes5.

The File Management Spectrum: From Manual to Enterprise

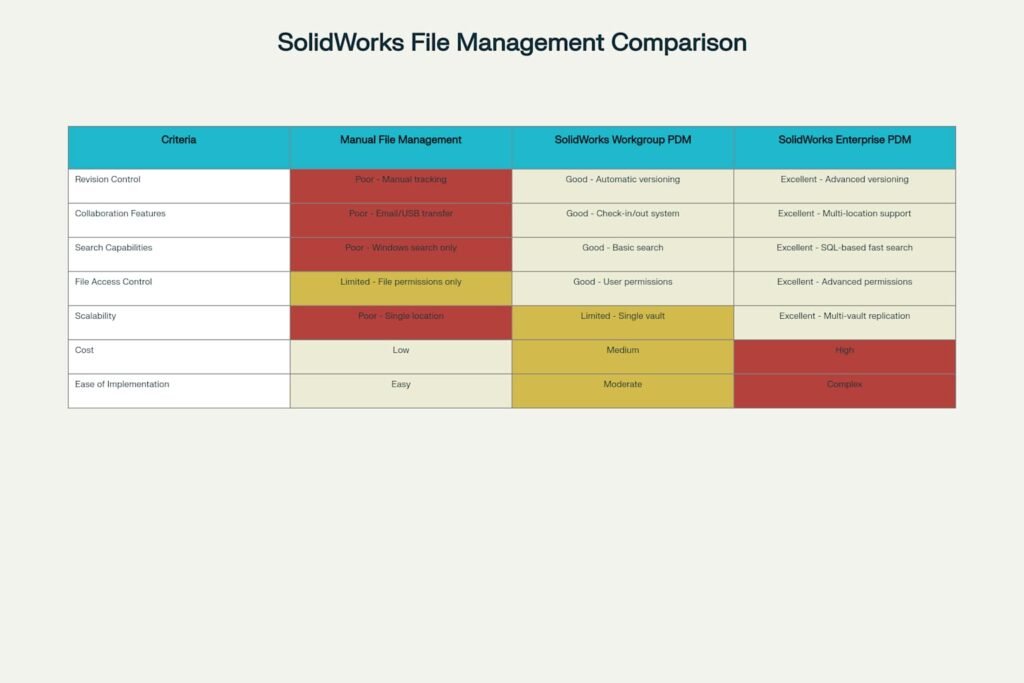

Comparison of SolidWorks File Management Approaches

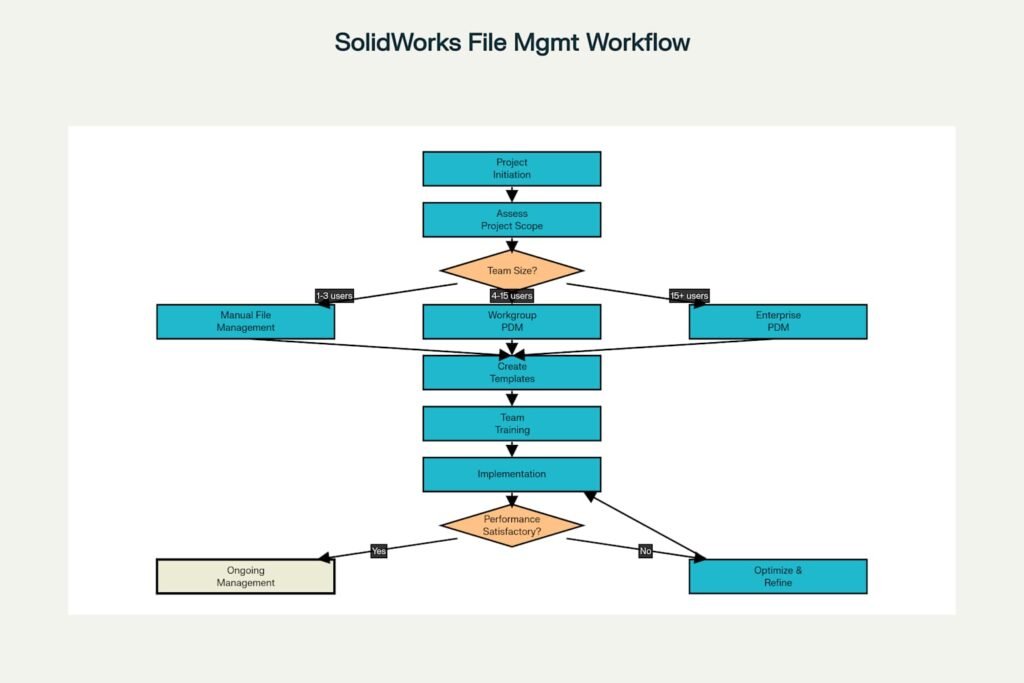

The journey from chaos to control doesn’t happen overnight, and different organizations require different approaches based on their size, complexity, and collaboration needs3. Understanding the spectrum of available solutions helps teams choose the right approach for their current situation while planning for future growth5.

Manual File Management: Simple but Limited

For very small teams—typically three engineers or fewer—manual file management can suffice if implemented thoughtfully10. This approach relies on shared network folders, clear naming conventions, and disciplined adherence to established procedures1. The primary advantage is simplicity: no additional software to purchase, install, or maintain10.

However, manual approaches scale poorly and become increasingly risky as teams and projects grow1. They offer no automated revision control, limited collaboration features, and rely entirely on human discipline to prevent conflicts10. As organizations expand beyond their initial team size, manual methods quickly become bottlenecks that constrain productivity and increase risk11.

The case study data reveals the stark limitations of manual approaches. Even for small projects, manual management results in 15% data loss risk and requires 2 hours weekly to resolve file-related issues. For medium-sized projects, these problems escalate dramatically, with 35% data loss risk and 8 hours weekly of lost productivity.

SolidWorks Workgroup PDM: The Middle Ground

SolidWorks Workgroup PDM bridges the gap between manual methods and enterprise solutions, making it ideal for single-location teams of 4-15 users5. This system provides automated revision control, check-in/check-out functionality, and basic search capabilities while remaining relatively simple to implement and maintain7.

Workgroup PDM addresses many of the core problems that plague manual systems5. It prevents multiple users from simultaneously editing the same files, maintains complete revision histories, and provides basic workflow management3. Users can clearly see who has files checked out and what version they’re working with, eliminating much of the confusion that characterizes manual approaches7.

The system’s limitations become apparent in larger, more distributed organizations5. Workgroup PDM uses a single vault structure that doesn’t replicate across multiple locations, making it unsuitable for teams spread across different offices or time zones1. Additionally, its search capabilities and workflow management features lag behind enterprise solutions5.

SolidWorks Enterprise PDM: The Complete Solution

For large, complex projects involving multiple locations and extensive collaboration, SolidWorks Enterprise PDM provides comprehensive data management capabilities5. Built on Microsoft SQL Server, it offers high performance, scalability, and advanced features that support even the most demanding engineering environments5.

Enterprise PDM’s multi-vault replication capability allows organizations to synchronize data across multiple locations, ensuring teams worldwide can access current information without network delays5. Its advanced search features leverage SQL database performance to quickly locate files based on metadata, custom properties, or content4. The system supports multiple workflows and revision schemes, accommodating diverse organizational needs and processes5.

Key components of product data management, including data centralization and workflowckonnect

The sophisticated workflow management capabilities enable organizations to formalize and optimize their development processes5. Electronic approval workflows ensure proper review and sign-off procedures, while automatic notifications keep stakeholders informed of changes and progress5. Advanced permissions systems provide granular control over who can access, modify, or approve different types of information5.

Implementation: Turning Plans into Reality

SolidWorks File Management Implementation Workflow

Having the right strategy on paper means nothing without proper implementation1. The most successful organizations follow systematic approaches that ensure smooth transitions from existing methods to new file management systems14. This process requires careful change management, comprehensive training, and ongoing optimization to achieve desired results1.

Documentation and Templates

The foundation of successful implementation lies in comprehensive documentation and standardized templates1. Written procedures eliminate ambiguity and ensure consistent practices across team members1. These documents should cover everything from file naming conventions to revision procedures, providing clear guidance that team members can reference when questions arise2.

Template development plays an equally critical role in ensuring consistency1. Well-designed part, assembly, and drawing templates automatically populate required metadata, enforce company standards, and streamline the modeling process2. Custom properties embedded in templates enable automatic bill-of-materials generation and support advanced search functionality1.

Training and Change Management

Even the best systems fail without proper user adoption, making training and change management essential components of successful implementations1. Organizations must invest time in thorough training programs that cover not just software functionality but also the reasoning behind new procedures1. When team members understand the benefits and consequences of proper file management, they’re more likely to embrace new approaches11.

SolidWorks Large Assembly Planning Checklist

Pre-Project Planning Phase

1. Project Scope Assessment

- Estimate total number of parts expected

- Identify key assemblies and sub-assemblies

- Determine complexity level (consumer product vs. industrial machinery)

- Define project timeline and milestones

2. Modeling Strategy Selection

- Skeleton Model Technique – For machines, plants, paper processing

- Visualizes important interfaces at all levels

- Best for mechanical systems with clear structural hierarchy

- Master Model Technique – For consumer products, car bodies, ducts

- Uses complex surfaces as base for components

- Results in multi-body parts

- Ideal for products with shared boundaries

3. File Naming Convention

- Choose between intelligent vs. dumb part numbering

- Define revision scheme (alphabetic, numeric, or hybrid)

- Establish unique file naming rules

- Document workflow for file creation and modifications

4. Template Development

- Create standardized part templates

- Develop assembly templates with common settings

- Design drawing templates with company standards

- Set up custom properties for automated data population

5. System Configuration

- Configure system-level performance settings

- Set up document properties templates

- Define visualization and display settings

- Establish backup and recovery procedures

File Management Implementation

6. PDM System Selection

- Manual Management – For teams under 3 people

- SolidWorks Workgroup PDM – For single-location teams up to 15 users

- SolidWorks Enterprise PDM – For large, multi-location teams

7. Folder Structure Design

- Create logical hierarchy based on part numbering

- Separate active projects from archived data

- Establish common library locations

- Define access permissions by user role

8. Training and Documentation

- Document all procedures and standards

- Conduct team training sessions

- Create quick reference guides

- Establish accountability measures

Ongoing Project Management

9. In-Context Relationship Management

- Keep in-context relations simple

- Limit to one master model where feasible

- Document all external references

- Regular cleanup of unused references

10. Performance Monitoring

- Regular performance evaluations

- Monitor file sizes and complexity

- Track rebuild times

- Implement lightweight and SpeedPak configurations

11. Change Control Process

- Define approval workflow for design changes

- Establish notification procedures

- Document impact assessment process

- Maintain revision history and audit trails

The HemoSonics case study illustrates the importance of comprehensive change management11. When the company implemented GrabCAD Workbench to manage their growing CAD database, they didn’t just deploy software—they fundamentally changed how their engineering team collaborated11. The transition required new workflows, updated procedures, and ongoing support to ensure adoption11.

Performance Monitoring and Optimization

Implementation doesn’t end with software deployment1. Successful organizations continuously monitor system performance, gather user feedback, and optimize their approaches based on real-world experience4. This involves tracking metrics like file access times, rebuild performance, and user productivity to identify bottlenecks and improvement opportunities4.

System-level settings can significantly impact performance, particularly for large assemblies1. Organizations should provide guidance on optimal configurations for different types of work, helping users balance functionality with performance4. Regular performance evaluations help identify when systems need upgrades or when processes require refinement1.

Advanced Strategies: Skeleton and Master Modeling

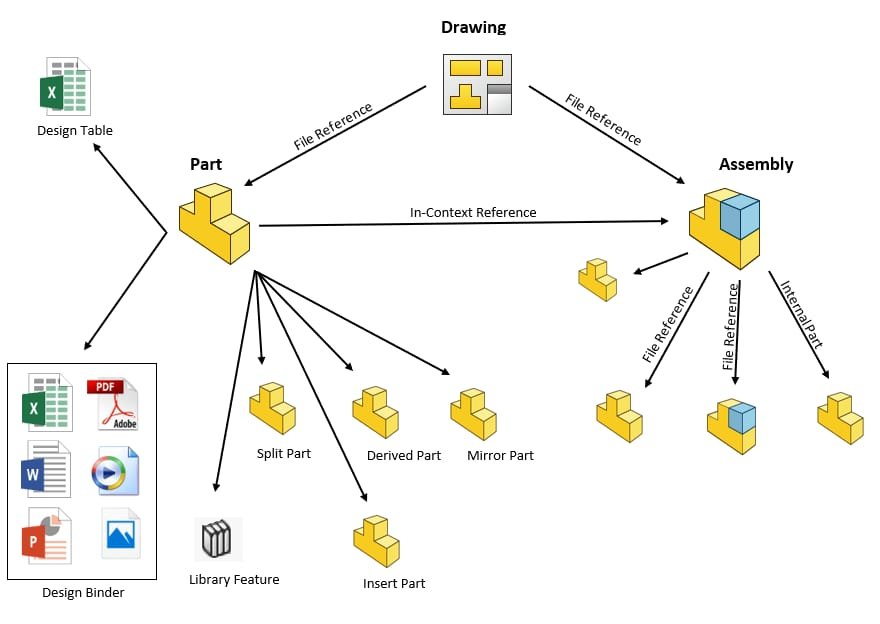

File references and relationships in SolidWorksmlc-cad

For organizations ready to take their large assembly management to the next level, advanced modeling techniques offer powerful approaches to controlling complexity and maintaining design intent6. These methods go beyond simple file organization to create intelligent relationships that propagate changes efficiently throughout complex designs24.

Skeleton Modeling: The Structural Approach

Skeleton modeling creates a framework of key sketches and reference geometry that defines the overall structure and critical interfaces of an assembly6. This technique excels in projects where spatial relationships and mounting interfaces drive the design, such as machinery, processing equipment, or building systems6. The skeleton serves as a master reference that guides component placement and ensures proper fit throughout the assembly19.

The power of skeleton modeling lies in its ability to separate interface definition from detailed component design6. Engineers can establish critical dimensions, mounting locations, and spatial envelopes before detailed parts are created19. When changes occur, modifications to the skeleton automatically propagate to all dependent components, maintaining design consistency across the entire assembly6.

Implementation requires careful planning to identify which elements belong in the skeleton versus individual components6. The skeleton should contain only the most critical information—overall dimensions, key interfaces, and essential reference geometry19. Including too much detail defeats the purpose, while omitting critical relationships undermines the approach’s effectiveness6.

Master Modeling: Surface-Driven Design

Master modeling takes a different approach, creating a single comprehensive model that contains all the geometry shared among multiple components1718. This technique proves particularly valuable for products where components share common surfaces or boundaries, such as automotive body panels, consumer electronics housings, or fluid-handling systems24.

The master model serves as both a design reference and a manufacturing guide24. Engineers create the overall form as a complete entity, then use various SolidWorks tools—including Save Bodies, Split, Insert Into New Part, and Insert Part—to derive individual components17. This ensures perfect fit between mating parts while enabling independent detailed design of each component20.

Fresh Consulting’s approach to master modeling demonstrates the technique’s power in real-world applications24. Their methodology involves creating a comprehensive master file that diagrams how various features and components relate spatially, then either “pushing” individual parts out or “pulling” the master model into each component as a starting reference24. This approach ensures that changes propagate automatically through all related parts while maintaining design intent24.

Measuring Success: The Return on Investment

The financial case for proper file management becomes compelling when organizations calculate the true cost of their current approaches versus systematic alternatives. The data reveals dramatic differences in productivity, risk, and total cost of ownership across different management strategies.

Organizations implementing SolidWorks Enterprise PDM see remarkable improvements in efficiency and risk reduction. Time lost to file management issues drops from an average of 11.67 hours weekly for manual approaches to just 1.17 hours for enterprise PDM users. Data loss risk plummets from 36.67% to 2.67%, while collaboration efficiency scores jump from 2.0 to 9.33 out of 10.

The total cost analysis reveals that enterprise solutions, despite higher upfront costs, often provide better value than manual approaches. While manual management appears “free,” the hidden costs of lost productivity create substantial ongoing expenses. Large projects using manual methods cost organizations an average of $97,500 annually in lost time, compared to just $12,800 for enterprise PDM implementations.

Key aspects of product data managementestuary

The Future of File Management

As SolidWorks and PDM technologies continue evolving, organizations that establish solid foundations today position themselves for future success1. Cloud-based solutions, artificial intelligence, and advanced analytics promise to further streamline file management and collaboration13. However, these technologies build upon the fundamental principles of proper planning, systematic organization, and disciplined processes1.

The most successful organizations view file management not as a necessary evil but as a competitive advantage1. By reducing time spent on administrative tasks, minimizing rework due to version conflicts, and enabling more effective collaboration, proper file management frees engineers to focus on what they do best: creating innovative solutions to complex problems14.

Conclusion: Your Path Forward

Sarah’s story doesn’t have to end in chaos9. With proper planning, appropriate tools, and systematic implementation, organizations of any size can achieve the benefits of professional file management1. The key lies in understanding your current needs, planning for future growth, and committing to the disciplined practices that make complex projects manageable14.

Whether you’re just starting your SolidWorks journey or looking to optimize existing processes, the principles remain the same: plan before you start, choose tools that match your needs, document your procedures, train your team, and continuously improve based on experience1. The investment in proper file management pays dividends in reduced stress, improved productivity, and successful project outcomes that keep both engineers and customers satisfied14.

The choice is yours: continue struggling with ad-hoc approaches that limit your potential, or embrace systematic file management that unlocks your team’s full capabilities1. In today’s competitive environment, organizations that master these fundamentals gain significant advantages over those that don’t14. Your future self—and your engineering team—will thank you for making the right choice today1.

- https://ppl-ai-file-upload.s3.amazonaws.com/web/direct-files/attachments/50648799/fcd9ddf0-7fcd-426e-85e2-84aeb594bde4/paste.txt

- https://www.javelin-tech.com/blog/2023/01/better-solidworks-file-organization/

- https://store.trimech.com/blog/7-best-practices-for-reusing-solidworks-files-between-co-workers

- https://blogs.solidworks.com/tech/2018/10/top-10-tips-tricks-for-working-with-large-assemblies.html

- https://beacon-india.com/solidworks-pdm/

- https://www.youtube.com/watch?v=jjE3nAI9xfo

- https://www.youtube.com/watch?v=hThh_zsVAy8

- https://www.youtube.com/watch?v=FHEh6u_Jkzk

- https://centralinnovation.com/resources/case-studies/goldacres-engineering-enhances-engineering-efficiency-and-data-management-with-solidworks-pdm/

- https://dezignstuff.com/manual-file-management/

- https://blog.grabcad.com/blog/2014/03/20/solidworks-files-organized/

- https://community.aws/content/2ktJD0P1ZjvQ11fNIIuvY5Dtl92/top-10-data-engineering-mistakes-and-how-to-fix-them?lang=en

- https://www.onshape.com/en/blog/absolutely-petrifying-things-about-traditional-cad-software

- https://www.smartsheet.com/content/successful-project-examples

- https://cadinfield.com/use-case-scenario-for-managing-file-references-with-solidworks/

- https://www.datamine.com/datafix/2022/05/common-pitfalls-data-project-failure

- https://www.engineersrule.com/using-a-master-model-with-solidworks/

- https://www.goengineer.com/blog/solidworks-tutorial-master-modeling-technique

- https://www.youtube.com/watch?v=CDtD7yQxMrw

- https://www.youtube.com/watch?v=p_NMXhZEyLc

- https://help.altair.com/hwdesktop/hwx/topics/skeleton/skeleton_introduction_c.htm

- https://productive.io/blog/precedence-diagramming-method/

- https://mfranzen.ca/docs/des/gen/solidworks-file-management.pdf

- https://www.freshconsulting.com/insights/blog/the-power-of-master-modeling-in-solidworks/

- https://2022.help.altair.com/2022/hwdesktop/hwx/topics/skeleton/skeleton_introduction_c.htm

- https://www.solidsolutions.ie/blog/2021/02/the-6-golden-rules-of-managing-data-in-solidworks/

- https://www.solidsolutions.co.uk/solidworks-videos/6-golden-rules-of-solidworks-file-management.aspx

- https://help.solidworks.com/2021/English/SolidWorks/sldworks/c_best_practice_file_distribution_best_practices.htm

- https://www.solidworks.com/customer-stories

- https://www.solidsolutions.co.uk/solidworks-industries/customer-stories.aspx

- https://www.engineering.com/solidworks-tutorial-master-modeling-for-padawans/