Girder Design for Efficient Defence Product Painting

Client: EPTEC

Industry: Defence Manufacturing

Service: Industrial Design & Engineering Drafting

Outcome: Fully developed design concept (not implemented)

EPTEC, a leading defence product manufacturer, engaged KEVOS® to streamline their painting process for large, complex components. Their core objective was clear:

Reduce manual handling, increase efficiency, and introduce mobility between painting stages through a purpose-designed girder system.

Challenges

EPTEC’s existing painting workflow presented several operational issues:

- Heavy manual handling of large defence components, increasing labour hours and safety risks.

- Static painting setups, requiring products to be manually transported between stations.

- Inefficient workflow, leading to delays, bottlenecks, and inconsistent throughput.

These challenges highlighted the need for a robust, mobile, and adaptable handling system.

Our Solution

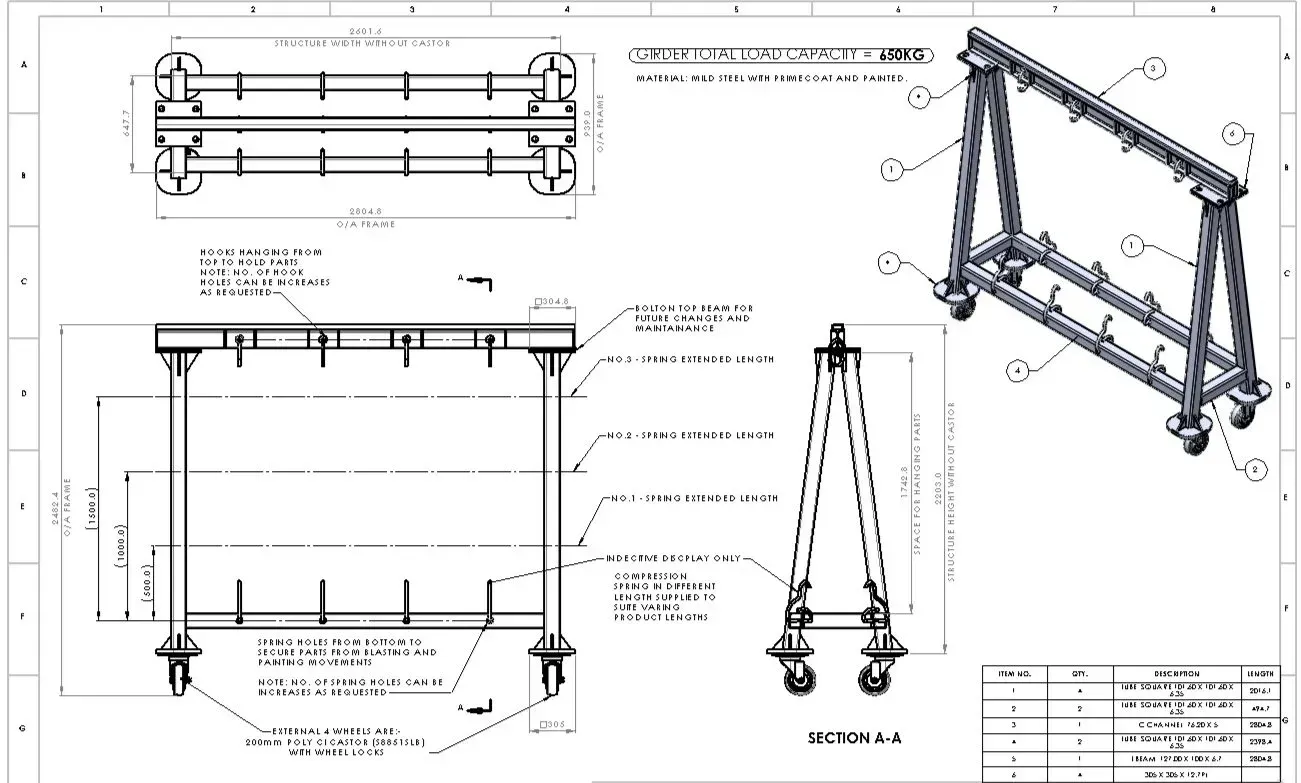

KEVOS® developed a modular girder system engineered specifically for EPTEC’s production environment.

Key Features of the Design

1. Modular Configuration

- Easily assembled and disassembled

- Adjustable to suit varying component sizes and shapes

- Provides long-term flexibility for EPTEC’s diverse product mix

2. High-Strength, Stable Structure

- Engineered to support significant loads

- Ensures accuracy and safety throughout the painting process

3. Rail-Based Mobility System

- Smooth movement between painting booths

- Dramatically reduces manual transport

- Minimises workflow downtime and handling errors

Design Process

Our approach combined practical industry insight with advanced engineering methods:

- Site assessments & stakeholder interviews

- Mapped pain points and workflow inefficiencies

- Concept development & refinement

- Multiple design options reviewed with EPTEC

- Iterative prototyping

- Progressive improvements based on operational feedback

- Virtual simulations

- Structural, mechanical, and mobility performance validated under real conditions

Outcome

Although the project did not proceed to fabrication due to budget limitations and internal stakeholder timing, the final design was well-received by EPTEC.

The girder system stands as a strong example of our capability to deliver innovative, practical, and industry-ready solutions for complex manufacturing challenges.

The completed concepts remain ready for future implementation as EPTEC’s operational needs evolve.

Why This Matters

This case study demonstrates KEVOS® commitment to:

- Improving industrial efficiency

- Enhancing safety and workflow design

- Delivering adaptable engineering solutions

- Adding value—even when projects pause before implementation

Thoughtful design endures. Even without immediate construction, the work completed provides EPTEC with a scalable blueprint for future investment.

Let’s Work Together

If your organisation needs expert engineering design or drafting support, we’re here to help.

KEVOS® provides practical, highly technical solutions tailored to industrial manufacturing environments.

Contact us today to discuss how we can collaborate on your next project.