Mastering SolidWorks Part Modelling

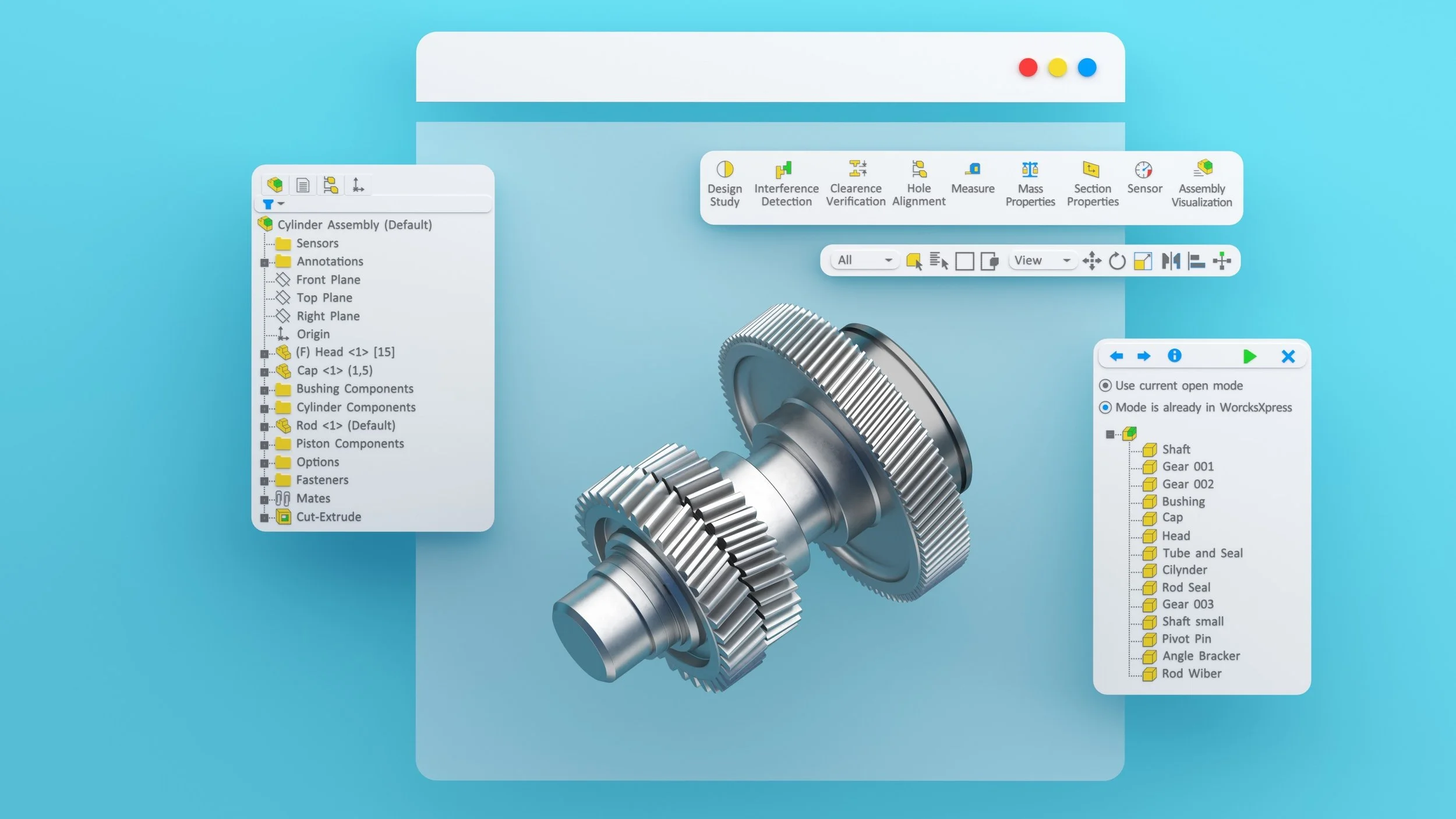

SolidWorks part modelling is the bread and butter of modern mechanical design. Whether you’re designing mining equipment in WA or consumer products in Sydney, the tool is incredibly powerful. However, there is a massive difference between a model that simply "looks right" and a robust, efficient model that rebuilds quickly and mates perfectly into larger assemblies.

Creating a quality 3D model starts with a plan. There is no "one size fits all" approach, but by following specific best practices, you can ensure your designs are accurate, efficient, and easy for your team to use.

Here is your comprehensive guide to efficient SolidWorks part modelling.

1. The Foundation: Planning Your Part

Before you even click "New Part," you need a strategy. Efficient assemblies rely entirely on the quality of their component parts. You need to establish your Design Intent immediately. Ask yourself the following questions:

Origin Placement: Where should the origin go? This decision affects how the part mates in the assembly later.

Symmetry: Does the part have symmetry? If so, align the origin with the planes of symmetry. This allows you to model half (or a quarter) of the part and mirror it, saving time.

Mating Requirements: How will this connect to the rest of the assembly?

Drawing Views: Which face represents the Front View on your detailed technical drawings?

Shutterstock

Start with the Right Template

Don’t waste time entering the same data for every project. A proper template saves hours over the course of a year. Your templates should have:

Document Properties: Units (millimetres, obviously!), image quality, and precision settings.

Materials: Set common materials (e.g., Aluminium 6061, Stainless 304) to capture mass properties early.

Custom Properties: Prefill fields like "Drawn By," "Company Name," and "Date" to streamline your BOMs (Bill of Materials).

2. Managing Features and Rebuild Speeds

A cluttered FeatureManager design tree is a nightmare to edit. To keep your model efficient:

Combine Features: Plan ahead to use the minimum number of features necessary.

Fillets and Chamfers Last: Place cosmetic fillets and chamfers at the very bottom of your design tree. This allows the model to rebuild faster during the design phase. You can even group them into a folder and suppress them while you work.

Use the Freeze Bar: For complex parts, use the Feature Freeze bar (drag it down from the top of the tree) to lock geometry that doesn't need to change, stopping it from rebuilding every time you make an edit.

Check Your Performance

Is your model lagging? Use the Performance Evaluation (formerly Feature Statistics) tool. It highlights exactly which features are chewing up your rebuild time, allowing you to suppress or redesign them.

3. The Power of Patterns and Symmetry

Why model the same thing twice?

Symmetry: Mirroring bodies is generally faster than mirroring features. If you have a symmetrical part, model one side and mirror the body at the end. This also simplifies mating in the assembly, as you can often use the primary planes (Front, Top, Right) as mating references.

Patterns: Use patterns smartly. Avoid patterning a pattern. Instead, create a single pattern that includes all necessary features. Move large patterns to the bottom of the tree so you can suppress them if they slow down your machine.

4. Configurations and Level of Detail

When working with large assemblies, "heavy" parts can kill your computer's performance. This is often due to excessive detail.

Simplified Configurations

Create a configuration specifically named "Simplified" for every complex part. In this configuration:

Suppress cosmetic fillets, chamfers, and text engraving.

Remove internal details not required for mating or interference checking.

Do NOT model threads. Helical threads create thousands of geometric faces (triangles) and will grind your system to a halt. Use a "Cosmetic Thread" or a simple texture map instead.

Avoid modelling springs physically; use a simple cylinder to represent the space the spring occupies.

By standardising the name "Simplified" across your team, you can set your main assembly to open all components in their simplified state automatically, drastically reducing load times.

5. In-Context Modelling: A Double-Edged Sword

In-context modelling (building a part while inside the assembly mode) is fantastic for ensuring parts fit together perfectly. It projects geometry from one part to another. However, it creates External References.

The Risk: If you move the original part or change the assembly, the in-context part might break or change unexpectedly.

Best Practice: Use in-context techniques to get the shape right, but consider removing the references before releasing the part for manufacturing. You can Lock references (to stop them updating temporarily) or Break them (to permanently sever the link) via the External References dialogue.

Look for the -> symbol in your tree. ->* means locked, and ->x means broken.

6. Handling Purchased Components (Fasteners)

When using the Toolbox or downloading models from suppliers:

Master vs. Copied Parts: For large teams, using "Copied Parts" (where a new file is created for each size) is often safer than "Master Parts" (one file driving all sizes), as it reduces network lag.

Strip the Detail: Vendor models often have ridiculous detail (like embossed text on a bolt head). Delete this immediately. You only need the mating surfaces and the bounding box for clearance.

7. Troubleshooting Errors

Finally, a rule to live by: Never ignore errors.

If you see a red "X" or a yellow warning triangle in your feature tree, fix it immediately. Ignoring a rebuild error is like building a house on a cracked slab; eventually, the whole thing will collapse.

Import Diagnostics: Run this immediately when importing a STEP or IGES file to fix "bad geometry" before you start adding features.

Check Tool: Use

Evaluate > Checkto find short edges or invalid geometry that might cause features to fail later.

By adhering to these principles, you’ll spend less time fighting the software and more time engineering great solutions. Happy modelling!