Extended Reality and Digital Transformation

The manufacturing landscape is undergoing a fundamental transformation that extends far beyond simple technology adoption. Companies achieving 300-800% return on investment through Extended Reality (XR) implementation are discovering that the true power lies not in replacing human capability, but in amplifying it. As 30% of global manufacturers already deploy XR solutions and projections indicate rapid growth toward millions of smart glasses and VR headsets in factories by 2030, the question for industrial leaders has shifted from whether to adopt these technologies to how to implement them strategically for maximum operational impact.

Extended Reality Adoption and ROI Analysis Across Industries (2025-2026)

Understanding the Extended Reality Ecosystem

Extended Reality encompasses Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR), each serving distinct but complementary functions in industrial environments. Unlike consumer applications, industrial XR focuses on solving critical operational challenges: reducing downtime, enhancing safety compliance, streamlining complex procedures, and transforming how knowledge is transferred across organizations.

Virtual Reality creates fully immersive training environments where workers can practice complex or hazardous procedures without risk to personnel or equipment. Companies like Boeing have demonstrated 40% error reduction in assembly processes through VR-guided training, while maintaining complete safety during skill development.

Augmented Reality overlays digital information onto real-world environments, providing workers with real-time instructions, diagnostic data, and quality control guidance. GE Aviation's pilot program with AR smart glasses eliminated the need for workers to pause assembly tasks to consult printed materials, resulting in faster completion times and improved accuracy.

VR-based occupational safety training in the electric power industry demonstrates how XR technology enhances safety and operational efficiency

Mixed Reality combines physical and digital environments, enabling real-time interaction with both virtual and physical objects. This technology proves particularly valuable for virtual prototyping and remote collaboration, allowing global teams to work together on complex projects without geographic constraints.

The Human-Centric Approach to Industrial Automation

Successful XR implementation begins with understanding that automation serves to enhance human capability rather than replace it. Research indicates that the most adaptable manufacturing workforces share four key traits: agility, responsiveness, flexibility, and predictability. XR technologies specifically address each of these characteristics by providing workers with enhanced situational awareness, immediate access to expert knowledge, and the ability to adapt quickly to changing conditions.

A professional using virtual reality technology to interact with a 3D model of industrial robotics on a factory floor

The shift toward Industry 5.0 emphasizes this human-centric approach, focusing on employee well-being and ergonomic solutions while leveraging advanced technologies like big data and Internet of Things integration. Rather than seeking to replace human workers, these advancements enhance employees' ability to perform their jobs more effectively and safely.

Manufacturing personnel report up to 30% increase in employee satisfaction when working with well-implemented XR systems, as these technologies eliminate frustrating inefficiencies and provide clear, actionable guidance for complex tasks. This satisfaction translates directly into improved retention rates and reduced training costs for new employees.

Transforming Production Environments Through XR Integration

Predictive Maintenance and Downtime Prevention

Traditional reactive maintenance approaches are being replaced by predictive systems that integrate XR technologies with IoT sensors and AI analytics. AR-enabled maintenance allows technicians to visualise equipment health data in real-time, access repair instructions hands-free, and receive guidance from remote experts without leaving their workstation.

Person using virtual reality to simulate industrial automation and safety training in a factory environment

Condition monitoring with sensors has reached a critical mass breakthrough, with IoT devices achieving widespread adoption at accessible price points. When combined with AR visualization, these sensors enable constant, real-time machine health monitoring that yields more effective maintenance, longer equipment lifespan, and higher-quality output.

Companies implementing XR-based predictive maintenance report up to 50% reduction in machine downtime while achieving labor productivity improvements of 30%. The key lies in providing maintenance teams with immediate access to diagnostic information, repair procedures, and expert consultation through immersive technologies.

Quality Control and Compliance Enhancement

XR technologies revolutionize quality assurance by providing workers with enhanced inspection capabilities and real-time compliance monitoring. Digital overlays highlight production tolerances and checkpoints, ensuring accuracy during inspections by incorporating quality checks directly into workers' field of view.

Thyssenkrupp Marine Systems' collaboration with Holo-Light demonstrates precision measurement and quality control in submarine construction, where AR enables engineers to overlay digital models onto physical components for millimeter-precise measurements and immediate identification of discrepancies.

Two workers using virtual reality headsets and simulators for industrial safety training with heavy machinery

Early studies suggest that inspection precision can be improved by as much as 40% with AR support, resulting in reduced scrap rates and improved product quality. This improvement stems from eliminating the cognitive load associated with cross-referencing multiple information sources while performing detailed inspections.

Advanced Training and Skill Development

VR safety training has demonstrated measurable impact on worker behavior and injury reduction. A comprehensive study on miners using VR safety training showed a 43% reduction in lost time from injury, while companies report that workers actually enjoy the immersive training experience compared to traditional methods.

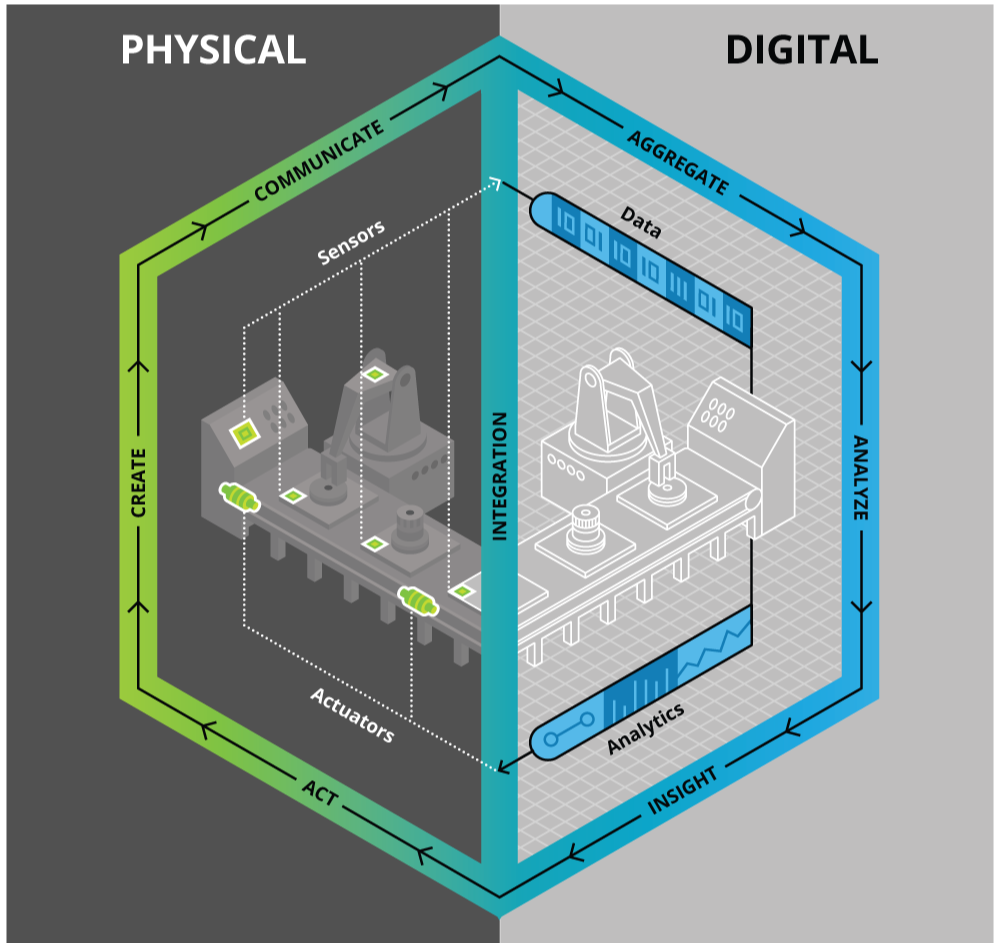

Visualization of Industry 4.0 principles showing the integration of physical industrial processes with digital data analytics through sensors, actuators, and digital twins for smart manufacturing

The effectiveness of VR training extends beyond safety to complex technical procedures. Workers can practice intricate assembly processes, equipment operation, and emergency response procedures in risk-free virtual environments that accurately replicate real-world conditions. This approach particularly benefits high-stakes industries like aerospace and energy, where errors during training can be extremely costly.

Training programs incorporating XR technologies report up to 96% reduction in training time—from 8 hours to 15 minutes for certain procedures—while simultaneously improving assessment scores by 12.5%. The immersive nature of XR training ensures better knowledge retention and faster skill acquisition compared to traditional classroom-based instruction.

AI-Generated Standard Operating Procedures: The Knowledge Revolution

The integration of Artificial Intelligence with XR technologies is transforming how standard operating procedures are created, maintained, and deployed across industrial operations. AI-powered SOP generation can transform basic instructions into comprehensive, step-by-step procedures complete with visual elements and contextual information.

Modern AI systems excel at creating manufacturing SOPs by automatically incorporating safety protocols, equipment-specific instructions, and quality control checkpoints. What once required days of manual documentation can now be accomplished in minutes, with AI ensuring consistency in terminology, formatting, and compliance requirements across all procedures.

Key advantages of AI-generated SOPs include:

Dynamic Content Creation: AI analyzes existing processes and generates detailed procedures with proper formatting and visual elements

Consistency Enforcement: Uniform terminology and formatting across all documentation eliminates confusion and compliance risks

Real-time Updates: Procedures automatically adjust based on equipment changes, regulatory updates, or process improvements

Accessibility Enhancement: AI-powered categorization and search capabilities help workers find relevant procedures 4x faster than traditional document management

Companies implementing AI-driven SOP systems report up to 32% reduction in quality deviations and significantly faster onboarding of production staff. The combination of AI-generated procedures with XR delivery creates a powerful system where workers receive real-time, contextual guidance precisely when and where they need it.

Digital Transformation on the Factory Floor

Digital Transformation Implementation Roadmap for Manufacturing

The Five-Phase Implementation Strategy

Successful digital transformation follows a structured approach that balances technological capability with organizational readiness. The most effective implementations progress through five distinct phases, each building upon previous investments while delivering measurable returns.

Phase 1: Foundation Building focuses on establishing basic IoT connectivity and sensor networks with investments ranging from $50,000 to $200,000. This phase typically delivers 150% ROI within 3-6 months by providing immediate visibility into previously opaque manufacturing processes.

Phase 2: System Integration connects data from shop floor to enterprise systems, requiring investments of $200,000 to $800,000 over 6-12 months. Organizations following the International Society of Automation's ISA-95 model for operations management achieve 250% ROI through improved data exchange and reduced manual processes.

Phase 3: Process Optimization implements AI and machine learning capabilities with $500,000 to $1.5 million investments over 9-18 months. This phase typically yields 350% ROI through predictive analytics and automated decision-making.

Phase 4: Advanced Analytics introduces digital twin technology and comprehensive predictive systems, requiring $800,000 to $2.5 million over 12-24 months but delivering 450% ROI through optimized operations and reduced unplanned downtime.

Phase 5: Autonomous Operations achieves self-healing systems and autonomous decision-making with investments of $1.5 to $5 million over 18-36 months, ultimately delivering 600% ROI through minimal human intervention requirements.

Overcoming Implementation Challenges

Digital transformation initiatives face three primary categories of challenges: technical, organizational, and cultural. Technical challenges include system integration complexity, data quality issues, and scalability requirements. Organizational challenges encompass change management, training and upskilling needs, and strategic alignment. Cultural challenges involve resistance to change and communication barriers between departments.

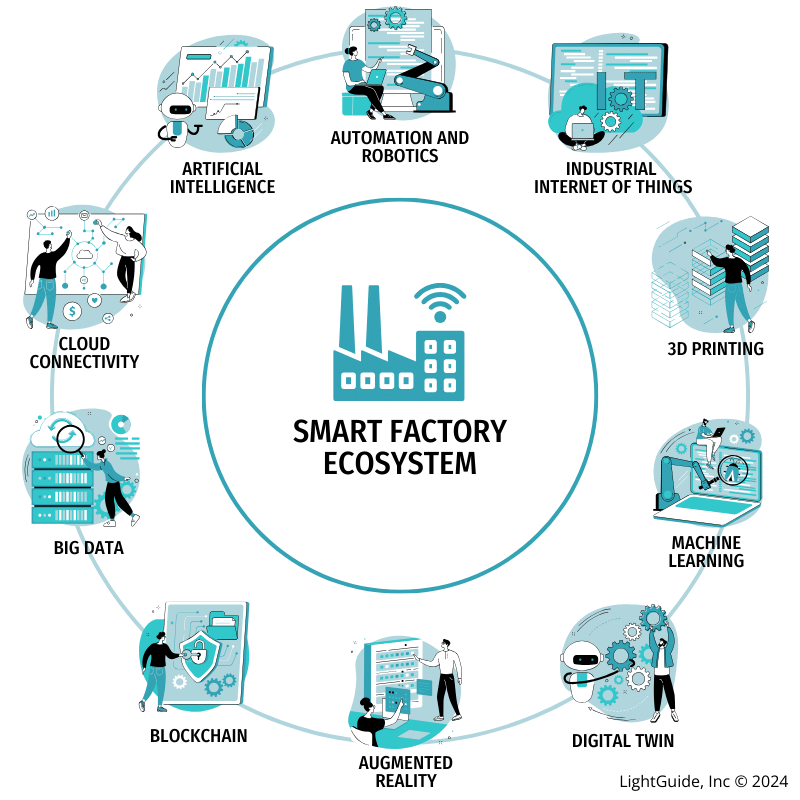

Key components of a smart factory ecosystem including AI, IoT, automation, digital twin, and augmented reality

Successful organizations address these challenges through comprehensive change management strategies that include continuous learning programs, cross-functional collaboration initiatives, and clear communication about technology benefits. Companies that treat workforce development as a strategic investment rather than a cost center consistently achieve better adoption rates and higher ROI from their digital transformation initiatives.

Industry Trends and Market Dynamics

Workforce Evolution and Skills Transformation

The manufacturing workforce is experiencing unprecedented change, with up to 3.8 million new employees needed between 2024 and 2033, yet nearly 1.9 million positions potentially remaining unfilled due to skills gaps. This challenge creates both risk and opportunity for organizations implementing XR technologies.

Traditional manufacturing skills are being transformed rather than eliminated. Manual assembly is evolving into automated systems management, basic machine operation becomes HMI and digital interface operation, and reactive maintenance transforms into predictive analytics interpretation. The key lies in providing workers with the training and tools necessary to evolve with these changing requirements.

Person using virtual reality headset for immersive industrial safety training with robotic equipment nearby

Companies successfully addressing the skills gap invest in continuous learning programs that combine technical training with soft skills development. These programs focus on adaptability, critical thinking, and problem-solving capabilities that enable workers to evolve as technology continues advancing.

Collaborative Robotics and Human-Machine Integration

Collaborative robots (cobots) represent a significant trend in human-machine cooperation, designed with advanced safety features that enable them to work alongside human workers rather than replacing them. These systems handle repetitive, dangerous, or precision-intensive tasks while allowing human workers to focus on higher-value activities requiring creativity, problem-solving, and interpersonal skills.

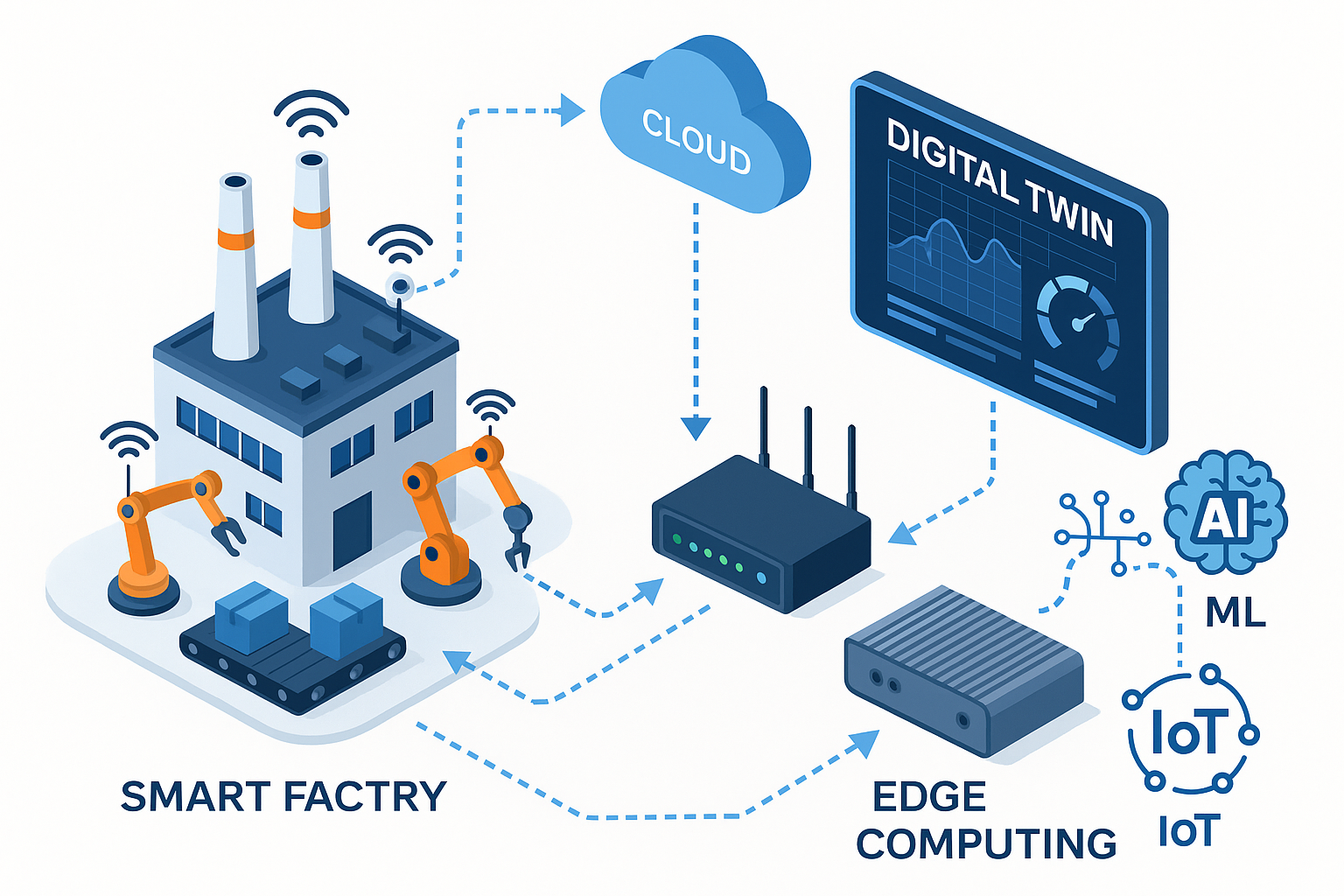

Smart factory ecosystem illustrating digital twin technology, IoT, AI, edge computing, and cloud integration powering connected manufacturing

A human worker in protective gear operates a collaborative robot arm using a control device in an industrial setting, exemplifying human-robot collaboration in Industry 4.0

The integration of cobots with XR technologies creates powerful synergies. AR interfaces allow workers to program and monitor collaborative robots intuitively, while VR training environments help workers develop confidence and competence in human-robot collaboration before working with physical systems.

Supply Chain Transparency and Resilience

XR technologies are transforming supply chain management by providing unprecedented visibility and accountability. AI, vendor management software, and blockchain technologies work together to create transparent, flexible supply chains that can adapt quickly to disruptions.

Collaborative supply chain platforms enhanced by XR visualisation allow manufacturers and suppliers to work together more effectively, identifying potential issues before they impact production and enabling rapid response to changing market conditions.

Practical Implementation Framework for Industrial Leaders

Getting Started: The Pilot Project Approach

Organisations achieve the highest success rates by beginning with focused pilot projects that demonstrate clear value before company-wide implementations. The most effective pilot programs target specific pain points where XR can deliver immediate, measurable improvements.

High-Impact Pilot Areas:

Remote Collaboration: Reducing travel costs and project delays through AR-enabled remote assistance

Training Programs: Implementing VR safety training for high-risk procedures

Quality Control: Using AR overlay systems for complex inspection processes

Maintenance Operations: Deploying AR-guided repair procedures for critical equipment

Successful pilots typically require 3-6 months for implementation and validation, with investments ranging from $25,000 to $100,000 depending on scope and complexity.

Building Internal Capability

Organisations achieving sustained success from XR implementation invest in building internal expertise rather than relying solely on external vendors. This approach includes establishing internal training academies, developing partnerships with educational institutions, and creating experiential learning environments.

Eclipse Automation's internal apprenticeship program exemplifies this approach, combining virtual learning with hands-on application to develop workers who understand both the company's specific automation infrastructure and broader manufacturing challenges. Companies report significant ROI when investing in internal training, as these programs develop both technical skills and deep organisational knowledge.

Technology Integration Strategy

XR solutions integrated with existing systems deliver 60% higher value than standalone implementations. Successful integration requires careful planning to ensure XR technologies enhance rather than replace current workflows.

Critical Integration Points:

Enterprise Resource Planning (ERP) systems for workflow coordination

Manufacturing Execution Systems (MES) for production scheduling and control

Computerised Maintenance Management Systems (CMMS) for predictive maintenance

Internet of Things (IoT) platforms for real-time data integration

Organisations following structured integration approaches report faster adoption rates, reduced implementation costs, and higher long-term ROI from their XR investments.

Measuring Success and Scaling Operations

Effective XR implementations establish clear metrics and measurement frameworks from the project's inception. Key performance indicators should align with business objectives and provide actionable insights for continuous improvement.

Essential Metrics:

Operational Efficiency: Reduction in task completion times, error rates, and rework requirements

Safety Performance: Decrease in workplace incidents, near-misses, and lost-time injuries

Training Effectiveness: Improvements in skill acquisition speed, knowledge retention, and assessment scores

Financial Impact: Cost savings, revenue enhancement, and return on investment calculations

Companies that establish comprehensive measurement frameworks achieve 40% better adoption rates and consistently higher ROI compared to organisations without systematic performance tracking.

Strategic Recommendations for Industrial Leaders

Executive-Level Considerations

Senior leadership plays a critical role in XR implementation success. Organisations with strong executive support and clear strategic alignment achieve consistently better outcomes than those treating XR as purely technical initiatives.

Leadership Actions:

Establish Clear Vision: Articulate how XR technologies align with broader business strategy and competitive positioning.

Allocate Sufficient Resources: Provide adequate funding for technology, training, and change management initiatives.

Champion Cultural Change: Model adoption behaviors and communicate the benefits of human-technology collaboration

Measure and Communicate Success: Share wins and learnings across the organisation to build momentum for broader adoption.

Operational Implementation Guidelines

Successful XR deployment requires careful attention to operational details and user experience design. Technologies that are difficult to use or poorly integrated into existing workflows will fail regardless of their technical capabilities.

Implementation Best Practices:

User-Centred Design: Involve end-users in technology selection and interface design decisions

Gradual Rollout: Implement in phases to allow for learning, adjustment, and optimisation

Comprehensive Training: Provide technical training, change management support, and ongoing assistance

Continuous Improvement: Establish feedback mechanisms and regular technology updates

Risk Management and Security Considerations

XR implementations must address data security, privacy concerns, and operational risks. Industrial XR systems often handle sensitive production data and require robust cybersecurity measures to prevent data breaches and unauthorised access.

Security Framework:

Data Encryption: Protect sensitive information throughout transmission and storage

Access Controls: Implement role-based permissions and authentication systems

Network Security: Use secure communication protocols and network segmentation

Regular Audits: Conduct periodic security assessments and vulnerability testing

Future Outlook and Emerging Opportunities

Technology Convergence and Innovation

The convergence of XR with artificial intelligence, edge computing, and 5G connectivity is creating new possibilities for industrial applications. Real-time data processing and AI-enhanced decision-making are enabling more sophisticated XR experiences that can adapt dynamically to changing conditions.

Digital twin partnerships are emerging as powerful tools for simulating production processes and optimising operations before implementing changes in real-world environments. This proactive approach reduces downtime and enhances productivity by allowing manufacturers to test improvements virtually before physical implementation.

Market Growth and Competitive Dynamics

The Extended Reality market is projected to reach $300 billion by 2024, with particularly strong growth in industrial applications. Organisations that establish XR capabilities now will define industry standards and maintain competitive advantages over those that delay implementation.

Early adopters are already seeing significant benefits from their XR investments, while late adopters face increasing pressure to catch up. The window for early adopter advantage is closing rapidly, making immediate action critical for maintaining a competitive position.

Preparing for the Next Wave

Future XR developments will likely include more sophisticated AI integration, improved hardware ergonomics, and enhanced interoperability between different XR platforms. Organisations should plan for these developments by establishing flexible technology architectures and maintaining focus on fundamental business objectives rather than specific technology solutions.

The most successful organisations will be those that view XR implementation as an ongoing capability development process rather than a one-time technology deployment. This perspective enables continuous improvement, adaptation to new opportunities, and sustained competitive advantage in rapidly evolving markets.

Transforming Industrial Excellence Through Extended Reality

Extended Reality represents far more than a technological upgrade—it embodies a fundamental shift toward human-centric industrial operations that amplify worker capability while driving unprecedented operational efficiency. Organisations achieving 300-800% returns on XR investments understand that success stems not from replacing human expertise, but from augmenting it with intelligent, context-aware systems that provide the right information at the right time.

The evidence is compelling: companies implementing comprehensive XR strategies report 50% reductions in machine downtime, 43% decreases in safety incidents, and 96% improvements in training efficiency. These results emerge when organisations approach XR implementation strategically, focusing on specific business challenges rather than pursuing technology for its own sake.

The path forward requires decisive action. While 30% of manufacturers have begun XR deployment, the remaining 70% face increasing competitive pressure as early adopters establish operational advantages. The five-phase implementation framework provides a clear roadmap for organisations at any stage of their digital transformation journey, from basic IoT connectivity through autonomous operations.

Industrial leaders must recognise that XR implementation success depends as much on change management and workforce development as on technology selection. Organisations that invest in comprehensive training programs, establish clear performance metrics, and maintain focus on human-machine collaboration consistently achieve better outcomes than those treating XR as purely technical initiatives.

The window for early adopter advantage is closing. Companies that act decisively to implement XR technologies will define the future of their industries, while those that hesitate will spend years explaining competitive disadvantages to stakeholders. The question for today's industrial leaders is not whether to embrace Extended Reality, but how quickly they can implement it to transform their operations and empower their workforce for the challenges ahead.

The future belongs to organisations that understand automation as a tool for human empowerment rather than replacement. Extended Reality provides the bridge between current capabilities and future possibilities, enabling manufacturers to unlock efficiency, enhance safety, and drive smarter operations that position them for sustained competitive success in an increasingly complex industrial landscape.